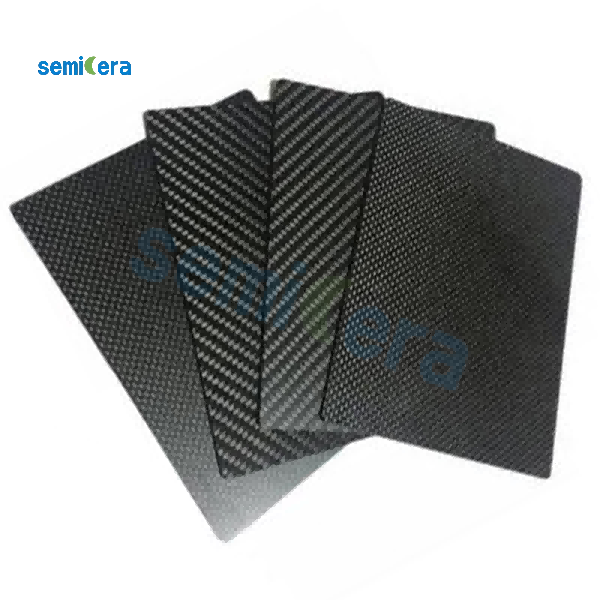

Carbon Carbon Composites:

Carbon/carbon composites are carbon matrix composites reinforced by carbon fibers and their fabrics. With low density (< 2.0g/cm3), high strength, high specific modulus, high thermal conductivity, low coefficient of expansion, good friction performance, good thermal shock resistance, high dimensional stability, is now in the application of more than 1650℃, the highest theoretical temperature up to 2600℃, so it is considered to be one of the most promising high temperature materials.

|

Technical Data of Carbon/Carbon Composite |

|

||

|

Index |

Unit |

Value |

|

|

Bulk density |

g/cm3 |

1.40~1.50 |

|

|

Carbon content |

% |

≥98.5~99.9 |

|

|

Ash |

PPM |

≤65 |

|

|

Thermal conductivity (1150℃) |

W/m.k |

10~30 |

|

|

Tensile strength |

Mpa |

90~130 |

|

|

Flexural Strength |

Mpa |

100~150 |

|

|

Compressive strength |

Mpa |

130~170 |

|

|

Shear strength |

Mpa |

50~60 |

|

|

Interlaminar Shear strength |

Mpa |

≥13 |

|

|

Electric resistivity |

Ω.mm2/m |

30~43 |

|

|

Coefficient of Thermal Expansion |

106/K |

0.3~1.2 |

|

|

Processing Temperature |

℃ |

≥2400℃ |

|

|

Military quality, full chemical vapor deposition furnace deposition, imported Toray carbon fiber T700 pre-woven 3D needle knitting |

|

||

It can be widely used in the high temperature environment of various structure, heater and vessel. Compared with the traditional engineering materials, carbon carbon composite has the following advantages:

1) High strength

2) High temperature up to 2000℃

3)Thermal shock resistance

4) Low coefficient of thermal expansion

5) Small thermal capacity

6) Excellent corrosion resistance and radiation resistance

Application:

1. Aerospace. Because of the composite material has good thermal stability, high specific strength and stiffness. It can be used for manufacturing of aircraft brakes, wing and fuselage, satellite antenna and a support structure, solar wing and shell, large carrier rocket shell, engine shell, etc..

2. The automobile industry.

3. The medical field.

4. Heat-insulation

5. Heating Unit

6. Ray-insulation