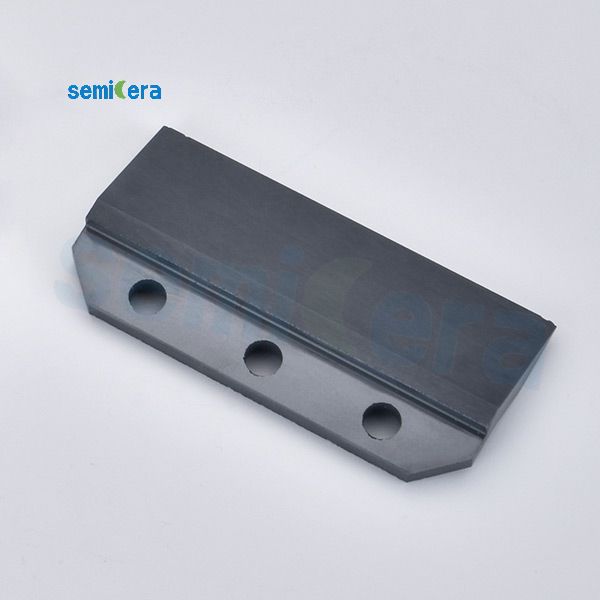

Silicon nitride is a gray ceramic with high fracture toughness, excellent heat shock resistance, and relatively impenetrable properties to molten metals.

Using these characteristics, it is applied to internal combustion engine parts such as automobile engine parts, welding machine blowpipe nozzles, etc., especially parts that need to be used in harsh environments such as overheating.

With its high wear resistance and high mechanical strength, its applications in bearing roller parts, rotating shaft bearings and semiconductor production equipment spare parts are constantly expanding.

|

Physical properties of silicon nitride materials |

Silicon nitride (Sic) |

|||

|

Colour |

Black |

|||

|

Main component content |

- |

|||

|

Main feature |

Light weight, wear resistance, high temperature resistance. |

|||

|

Main use |

Heat resistant parts, wear resistant parts, corrosion resistant parts. |

|||

|

Density |

g/cc |

3.2 |

||

|

Hydroscopicity |

% |

0 |

||

|

Mechanical characteristic |

Vickers hardness |

GPa |

13.9 |

|

|

Bending strength |

MPa |

500-700 |

||

|

Compressive strength |

MPa |

3500 |

||

|

Young's modulus |

GPA |

300 |

||

|

Poisson's ratio |

- |

0.25 |

||

|

Fracture toughness |

MPA·m1/2 |

5-7 |

||

|

Thermal characteristic |

Coefficient of linear expansion |

40-400℃ |

x10-6/℃ |

2.6 |

|

Thermal conductivity |

20° |

W/(m·k) |

15-20 |

|

|

Specific heat |

J/(kg·k)x103 |

|

||

|

Electrical characteristic |

Volume resistivity |

20℃ |

Ω·cm |

>1014 |

|

Dielectric strength |

|

KV/mm |

13 |

|

|

Dielectric constant |

|

- |

|

|

|

Dielectric loss coefficient |

|

x10-4 |

|

|

|

Chemical characteristic |

Nitric acid |

90℃ |

Weight loss |

<1.0<> |

|

Vitriol |

95℃ |

<0.4<> |

||

|

Sodium hydroxide |

80℃ |

<3.6<> |

||