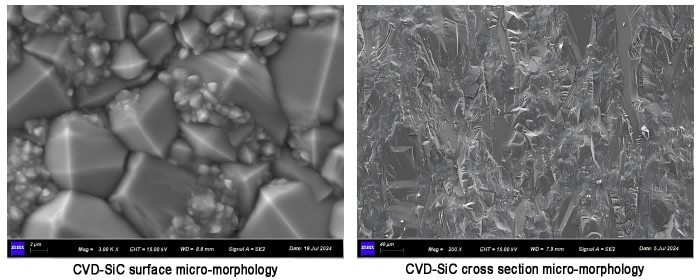

CVD Bulk Silicon Carbide (SiC)

Overview: CVD bulk silicon carbide (SiC) is a highly sought-after material in plasma etching equipment, rapid thermal processing (RTP) applications, and other semiconductor manufacturing processes. Its exceptional mechanical, chemical, and thermal properties make it an ideal material for advanced technology applications that demand high precision and durability.

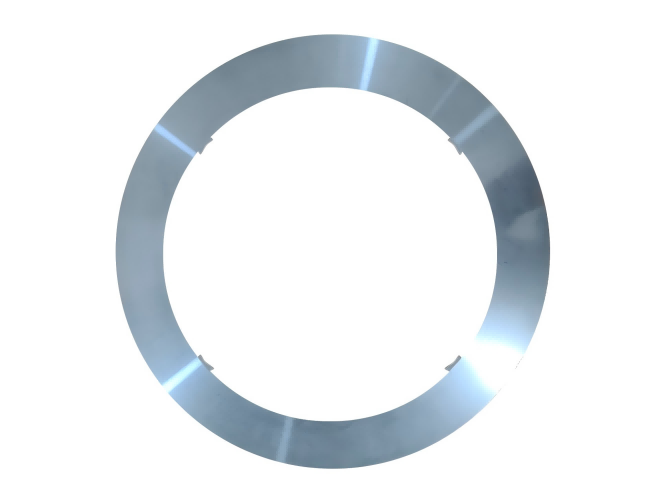

Applications of CVD Bulk SiC: Bulk SiC is crucial in the semiconductor industry, particularly in plasma etching systems, where components like focus rings, gas showerheads, edge rings, and platens benefit from SiC’s outstanding corrosion resistance and thermal conductivity. Its use extends to RTP systems due to SiC’s capability to withstand rapid temperature fluctuations without significant degradation.

In addition to etching equipment, CVD bulk SiC is favored in diffusion furnaces and crystal growth processes, where high thermal stability and resistance to harsh chemical environments are required. These attributes make SiC the material of choice for high-demand applications involving high temperatures and corrosive gases, such as those containing chlorine and fluorine.

Advantages of CVD Bulk SiC Components:

• High Density: With a density of 3.2 g/cm³, CVD bulk SiC components are highly resistant to wear and mechanical impact.

• Superior Thermal Conductivity: Offering thermal conductivity of 300 W/m·K, bulk SiC efficiently manages heat, making it ideal for components exposed to extreme thermal cycles.

• Exceptional Chemical Resistance: The low reactivity of SiC with etching gases, including chlorine and fluorine-based chemicals, ensures prolonged component life.

• Adjustable Resistivity: CVD bulk SiC’s resistivity can be customized within the range of 10⁻²–10⁴ Ω-cm, making it adaptable to specific etching and semiconductor manufacturing needs.

• Thermal Expansion Coefficient: With a thermal expansion coefficient of 4.8 x 10⁻⁶/°C (25–1000°C), CVD bulk SiC resists thermal shock, maintaining dimensional stability even during rapid heating and cooling cycles.

• Durability in Plasma: Exposure to plasma and reactive gases is inevitable in semiconductor processes, but CVD bulk SiC offers superior resistance to corrosion and degradation, reducing replacement frequency and overall maintenance costs.

Technical Specifications:

• Diameter: Greater than 305 mm

• Resistivity: Adjustable within 10⁻²–10⁴ Ω-cm

• Density: 3.2 g/cm³

• Thermal Conductivity: 300 W/m·K

• Thermal Expansion Coefficient: 4.8 x 10⁻⁶/°C (25–1000°C)

Customization and Flexibility: At Semicera Semiconductor, we understand that every semiconductor application may require different specifications. That's why our CVD bulk SiC components are fully customizable, with adjustable resistivity and tailored dimensions to suit your equipment needs. Whether you're optimizing your plasma etching systems or looking for durable components in RTP or diffusion processes, our CVD bulk SiC delivers unparalleled performance.