Description

Silicon carbide ceramics have excellent mechanical properties at room temperature, such as high strength, high hardness, high elastic modulus,etc., it also has excellent high-temperature stability like high thermal conductivity, low thermal expansion coefficient, and good specific stiffness and optical processing performance.

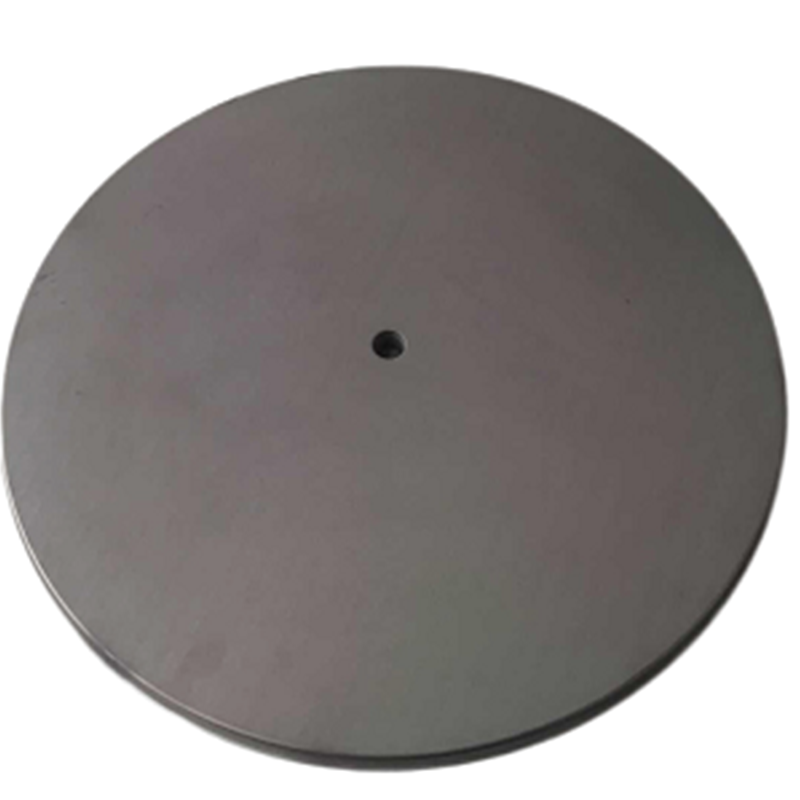

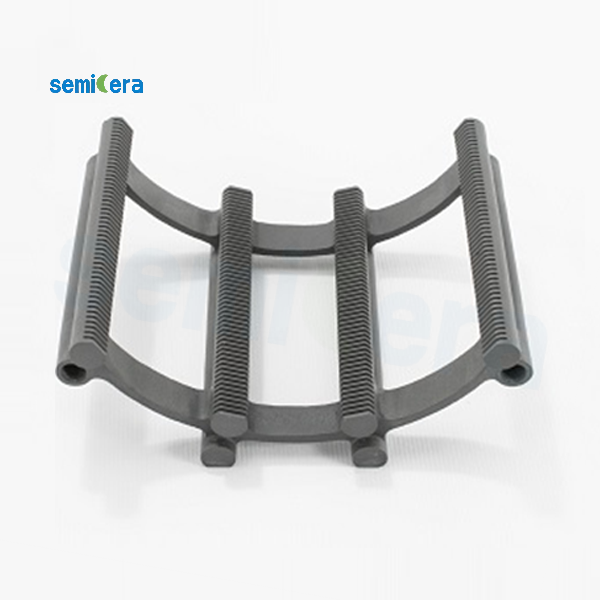

They are especially suitable for producing precision ceramic parts for integrated circuit equipments such as lithography machines, mainly used to manufacture the SiC carrier/susceptor, SiC wafer boat, sucking disc, water cooling plate, precision measuring reflector, grating and other ceramic structural parts

Advantages

High temperature resistance: normal use at 1800 ℃

High thermal conductivity: equivalent to graphite material

High hardness: hardness second only to diamond, boron nitride

Corrosion resistance: strong acid and alkali have no corrosion to it, the corrosion resistance is better than tungsten carbide and alumina

Light weight: low density, close to aluminum

No deformation: low coefficient of thermal expansion

Thermal shock resistance: it can withstand sharp temperature changes, resist thermal shock, and has stable performance

Silicon carbide carrier such as sic etching carrier, ICP etching susceptor, are widely used in semiconductor CVD, vacuum sputtering etc. We can provide customers with customized wafer carriers of silicon and silicon carbide materials to meet different applications.

Advantages

| Property | Value | Method |

| Density | 3.21 g/cc | Sink-float and dimension |

| Specific heat | 0.66 J/g °K | Pulsed laser flash |

| Flexural strength | 450 MPa560 MPa | 4 point bend, RT4 point bend, 1300° |

| Fracture toughness | 2.94 MPa m1/2 | Microindentation |

| Hardness | 2800 | Vicker’s, 500g load |

| Elastic ModulusYoung’s Modulus | 450 GPa430 GPa | 4 pt bend, RT4 pt bend, 1300 °C |

| Grain size | 2 – 10 µm | SEM |

Company Profile

WeiTai Energy Technology Co., Ltd. is a leading supplier of advanced semiconductor ceramics and the only manufacturer in China that can simultaneously provide high-purity silicon carbide ceramic(especially the Recrystallized SiC) and CVD SiC coating. In addition, our company is also committed to ceramic fields such as alumina, aluminum nitride, zirconia, and silicon nitride, etc.

Our main products including: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat(Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, as well as the CVD SiC coating and TaC coating. The products mainly used in the semiconductor and photovoltaic industries, such as equipment for crystal growth, epitaxy, etching, packaging, coating and diffusion furnaces,etc.

Transport

-

Special Design for Hot Sale Factory Price Refra...

-

Popular Design for for Heat Insulation Resistan...

-

Wholesale OEM High Precision Manufacturing Cera...

-

Special Design for Insulation Material Heat Res...

-

Ordinary Discount Electric Double Spiral Cerami...

-

Fixed Competitive Price Factory Price Custom In...