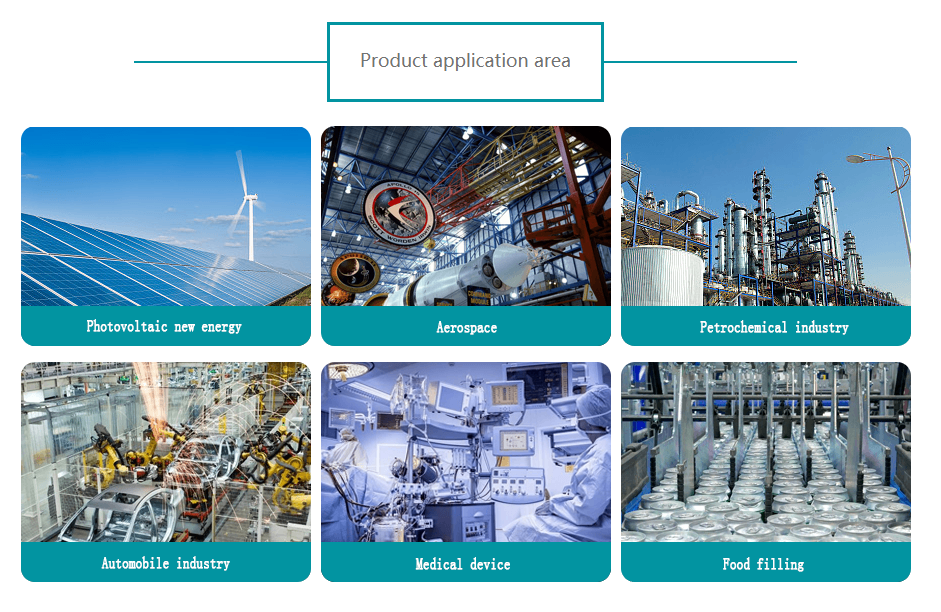

Application of SiC Cantilever Beam

SiC Cantilever paddle is being used in the diffusion coating furnace of the photovoltaic industry for coating monocrystalline and polycrystalline silicon wafers. Its characteristic enables it to withstand high temperature and corrosion, giving it a long life span.

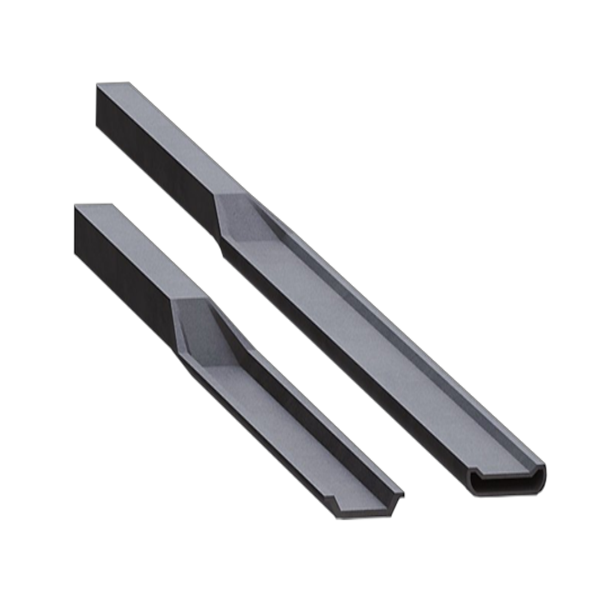

The SiC Cantilever paddle delivers SiC boats /quartz boats which carry silicon wafers into the high temperature diffusion coating furnace tube.

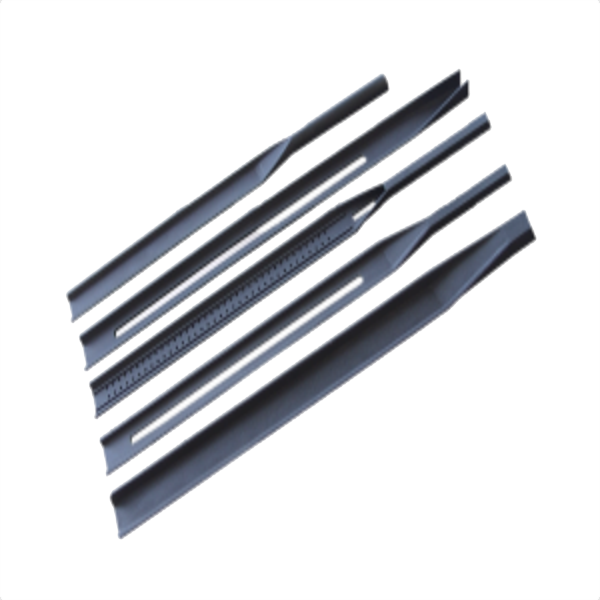

The length of our SiC Cantilever paddle ranges from 1,500 to 3,500 mm. SiC Cantilever paddle's dimension can be tailor made according to customer's specification.

Semicera Semiconductor Technology Co., Ltd. is a professional research, development, production and sales of silicon carbide ceramic products. Since its establishment in 2016, Semicera Energy has mastered isostatic pressing molding process, thousand pressing molding process grouting molding process and vacuum extrusion molding process. Our company uses 6 silicon carbide ceramic sintering production lines, has 8 CNC, 6 precision grinding machines, can also provide you with silicon carbide ceramic sintered products, but also can provide silicon carbide ceramics, alumina ceramics, aluminum nitride ceramics, zirconia ceramics processing services.