Product details

|

Product name |

Graphite Felt |

|

Chemical Composition |

Carbon fiber |

|

Bulk density |

0.12-0.14g/cm3 |

|

Carbon content |

>=99% |

|

Tensile Strength |

0.14Mpa |

|

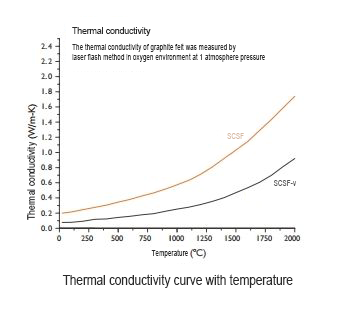

Thermal conductivity(1150℃) |

0.08~0.14W/mk |

|

Ash |

<=0.005% |

|

Crushing stress |

8-10N/cm |

|

Thickness |

1-10mm |

|

Processing temperature |

2500(℃) |

Currently available in four specifications, each available in rolls, parts and pre-rolled felt tubes:

SCSF: High purity graphite felt, better thermal conductivity, heat treatment temperature of more than 1900℃

SCSF-p: Ultra-high purity SCSF-B graphite felt

SCSF-v: High purity graphite felt, heat treatment temperature of more than 2650℃, low thermal conductivity

SCSF-v-p: Ultra-high purity SCSF-D graphite felt

Properties :

-Outstanding thermal stability

-High mechanical strength

-Good electrical and thermal conductivity

-Excellent resistance to thermal shock and corrosion

-High material purity

-High electriccal load capacity

-Uniform temperature profile

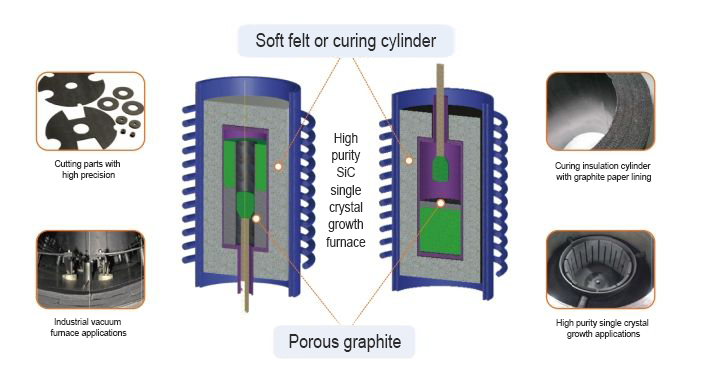

Fields of applications:

-Vacuum furnaces

-Inert gas furnaces

-Heat treatment

(hardening, carbonization, brazing, etc.)

-Carbon fiber production

-Hard metal production

-Sintering applications

-Technical ceramic production

-CVD/PVD coasting