Silicon carbide is a new type of ceramics with high cost performance and excellent material properties. Due to features like high strength and hardness, high temperature resistance, great thermal conductivity and chemical corrosion resistance, Silicon Carbide can almost withstand all chemical medium. Therefore, SiC are widely used in oil mining, chemical, machinery and airspace, even nuclear energy and the military have their special demands on SIC. Some normal application we can offer are seal rings for pump, valve and protective armor etc.

We are able to design and manufacture according to your specific dimensions with good quality and reasonable deliver time.

We can provide stable and reliable silicon carbide crystal boats, silicon carbide paddles, silicon carbide furnace tubes for the 4 inch to 6 inch semiconductor wafer industry. The purity can reach 99.9% without polluting the wafer.

Silicon carbide furnace tube is mainly used for: 4-6 inch silicon wafer LTO= silica, SIPOS= oxy-polysilicon, SI3N4= silicon nitride, PSG= phosphosilicon glass, POLY= polysilicon film growth. It is the raw material gas (or liquid source gasification) activated by thermal energy to generate a solid film on the surface of the substrate. Low pressure chemical vapor deposition is carried out at low pressure, due to the low pressure, the average free path of gas molecules is large, so that the uniformity of the grown film is good, and the substrate can be vertically placed and the amount of loading is large, especially suitable for large-scale integrated circuits, discrete devices, power electronics, optoelectronic devices and optical fiber and other industries of industrial production special equipment.

Applications:

-Wear-resistant Field: bushing, plate, sandblasting nozzle,cyclone lining, grinding barrel,etc...

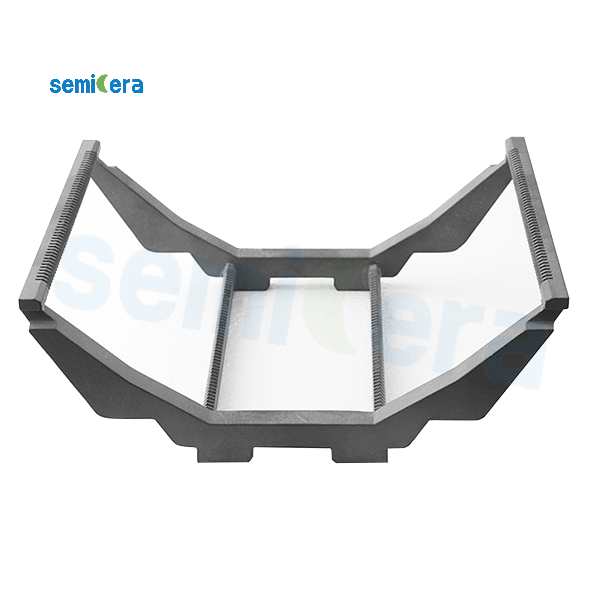

-High Temperature Field: siC Slab, Quenching Furnace Tube,Radiant Tube,crucible,Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC boat,Kiln car Structure,Setter,etc.

-Military Bulletproof Field

-Silicon Carbide Semiconductor: SiC wafer boat, sic chuck,sic paddle, sic cassette, sic diffusion tube, wafer fork, suction plate, guideway,etc.

-Silicon Carbide Seal Field: all kinds of sealing ring, bearing, bushing, etc.

-Photovoltaic Field: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller,etc.

-Lithium Battery Field

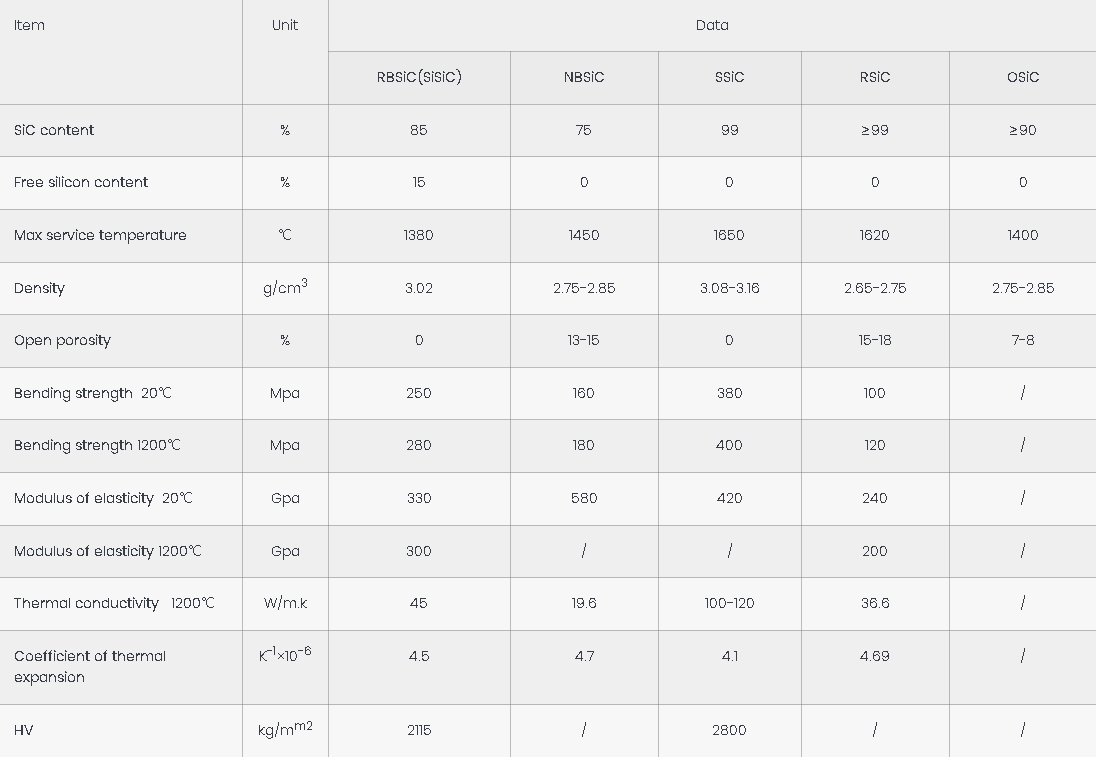

Technical Parameters