Advantages of LMJ processing

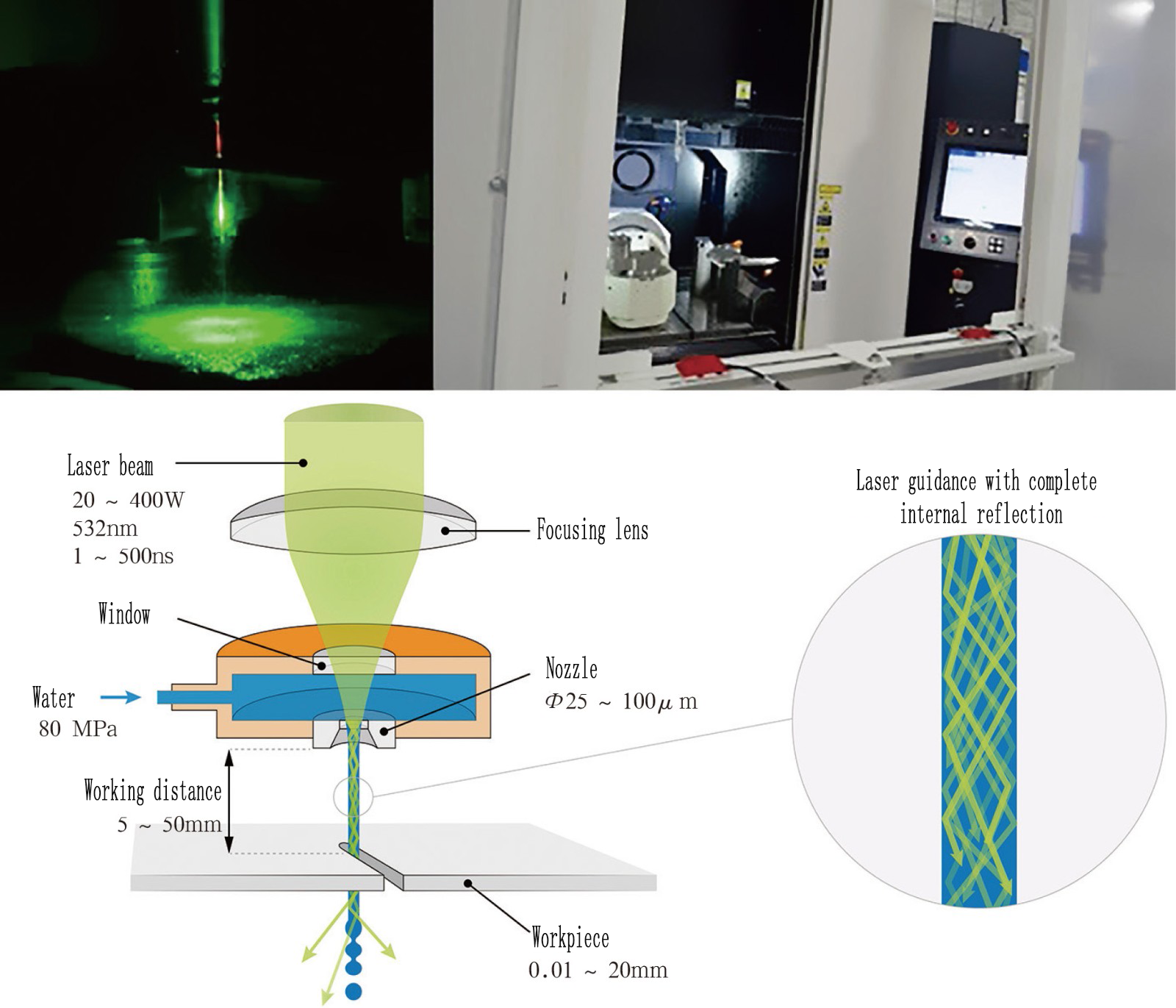

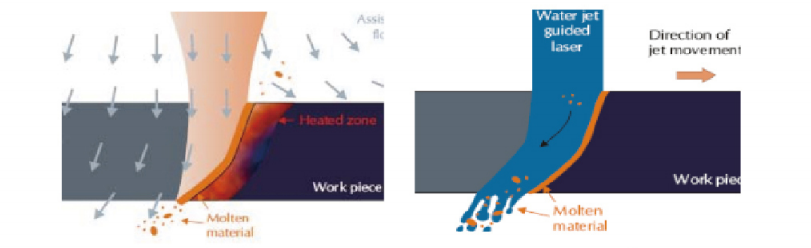

The inherent defects of regular laser processing can be overcome by the smart use of laser Laser micro jet (LMJ) technology to propagate the optical characteristics of water and air. This technology allows the laser pulses fully reflected in the processed high purity water jet in an undisturbed manner to reach the machining surface as in optical fiber.

The main features of LMJ technology are:

1. The laser beam is a columnar (parallel) structure.

2. The laser pulse is transmitted in the water jet like an optical fiber, without any environmental interference.

3. The laser beam is focused in the LMJ equipment, and the height of the machined surface does not change during the entire processing process, so it does not need to continue focusing with the change of the processing depth during the processing.

4. Clean the surface continuously.

5. In addition to the ablation of the workpiece material by each laser pulse, every single unit time from the beginning of each pulse to the next pulse, the processed material is in the real-time cooling water state for about 99% of the time, which almost eliminates the heat affected zone and the remelt layer, but maintains the high efficiency of the processing.

|

General specification |

LCSA-100 |

LCSA-200 |

|

Countertop volume |

125 x 200 x 100 |

460×460×300 |

|

Linear axis XY |

Linear motor. Linear motor |

Linear motor. Linear motor |

|

Linear axis Z |

100 |

300 |

|

Positioning accuracy μm |

+ / - 5 |

+ / - 3 |

|

Repeated positioning accuracy μm |

+ / - 2 |

+ / - 1 |

|

Acceleration G |

0.5 |

1 |

|

Numerical control |

3-axis |

3-axis |

|

Laser |

|

|

|

Laser type |

DPSS Nd: YAG |

DPSS Nd: YAG, pulse |

|

Wavelength nm |

532/1064 |

532/1064 |

|

Rated power W |

50/100/200 |

200/400 |

|

Water jet |

|

|

|

Nozzle diameter μm |

25-80 |

25-80 |

|

Nozzle pressure bar |

100-600 |

0-600 |

|

Size/Weight |

|

|

|

Dimensions (Machine) (W x L x H) |

1050 x 800 x 1870 |

1200 x 1200 x 2000 |

|

Dimensions (control cabinet) (W x L x H) |

700 x 2300 x 1600 |

700 x 2300 x 1600 |

|

Weight (equipment) kg |

1170 |

2500-3000 |

|

Weight (control cabinet) kg |

700-750 |

700-750 |

|

Comprehensive energy consumption |

|

|

|

Input |

AC 230 V +6%/ -10%, unidirectional 50/60 Hz ±1% |

AC 400 V +6%/-10%, 3-phase50/60 Hz ±1% |

|

Peak value |

2.5kVA |

2.5kVA |

|

Join |

10 m power cable: P+N+E, 1.5 mm2 |

10 m power cable: P+N+E, 1.5 mm2 |

|

Semiconductor industry user application range |

≤4 inches round ingot ≤4 inches ingot slices ≤4 inches ingot scribing

|

≤6 inches round ingot ≤6 inch ingot slices ≤6 inches ingot scribing The machine meets the 8-inch circular/slicing/slicing theoretical value, and the specific practical results need to be optimized cutting strategy |