Silicon carbide (SiC) single crystal material has a large band gap width (~Si 3 times), high thermal conductivity (~Si 3.3 times or GaAs 10 times), high electron saturation migration rate (~Si 2.5 times), high breakdown electric field (~Si 10 times or GaAs 5 times) and other outstanding characteristics.

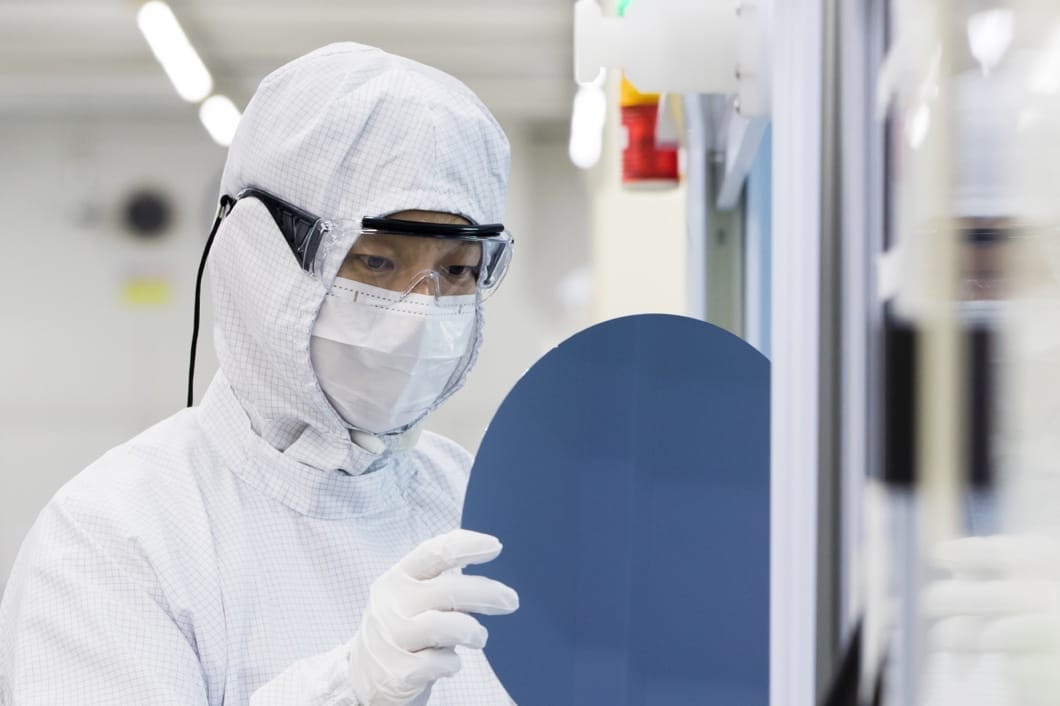

Semicera energy can provide customers with high-quality Conductive (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) silicon carbide substrate; In addition, we can provide customers with homogeneous and heterogeneous silicon carbide epitaxial sheets; We can also customize the epitaxial sheet according to the specific needs of customers, and there is no minimum order quantity.

|

Items |

Production |

Research |

Dummy |

|

Crystal Parameters |

|||

|

Polytype |

4H |

||

|

Surface orientation error |

<11-20 >4±0.15° |

||

|

Electrical Parameters |

|||

|

Dopant |

n-type Nitrogen |

||

|

Resistivity |

0.015-0.025ohm·cm |

||

|

Mechanical Parameters |

|||

|

Diameter |

99.5 - 100mm |

||

|

Thickness |

350±25 μm |

||

|

Primary flat orientation |

[1-100]±5° |

||

|

Primary flat length |

32.5±1.5mm |

||

|

Secondary flat position |

90° CW from primary flat ±5°. silicon face up |

||

|

Secondary flat length |

18±1.5mm |

||

|

TTV |

≤5 μm |

≤10 μm |

≤20 μm |

|

LTV |

≤2 μm(5mm*5mm) |

≤5 μm(5mm*5mm) |

NA |

|

Bow |

-15μm ~ 15μm |

-35μm ~ 35μm |

-45μm ~ 45μm |

|

Warp |

≤20 μm |

≤45 μm |

≤50 μm |

|

Front(Si-face) roughness(AFM) |

Ra≤0.2nm (5μm*5μm) |

||

|

Structure |

|||

|

Micropipe density |

≤1 ea/cm2 |

≤5 ea/cm2 |

≤10 ea/cm2 |

|

Metal impurities |

≤5E10atoms/cm2 |

NA |

|

|

BPD |

≤1500 ea/cm2 |

≤3000 ea/cm2 |

NA |

|

TSD |

≤500 ea/cm2 |

≤1000 ea/cm2 |

NA |

|

Front Quality |

|||

|

Front |

Si |

||

|

Surface finish |

Si-face CMP |

||

|

Particles |

≤60ea/wafer (size≥0.3μm) |

NA |

|

|

Scratches |

≤2ea/mm. Cumulative length ≤Diameter |

Cumulative length≤2*Diameter |

NA |

|

Orange peel/pits/stains/striations/ cracks/contamination |

None |

NA |

|

|

Edge chips/indents/fracture/hex plates |

None |

NA |

|

|

Polytype areas |

None |

Cumulative area≤20% |

Cumulative area≤30% |

|

Front laser marking |

None |

||

|

Back Quality |

|||

|

Back finish |

C-face CMP |

||

|

Scratches |

≤5ea/mm,Cumulative length≤2*Diameter |

NA |

|

|

Back defects (edge chips/indents) |

None |

||

|

Back roughness |

Ra≤0.2nm (5μm*5μm) |

||

|

Back laser marking |

1 mm (from top edge) |

||

|

Edge |

|||

|

Edge |

Chamfer |

||

|

Packaging |

|||

|

Packaging |

The inner bag is filled with nitrogen and the outer bag is vacuumed. Multi-wafer cassette, epi-ready. |

||

|

*Notes: "NA" means no request Items not mentioned may refer to SEMI-STD. |

|||