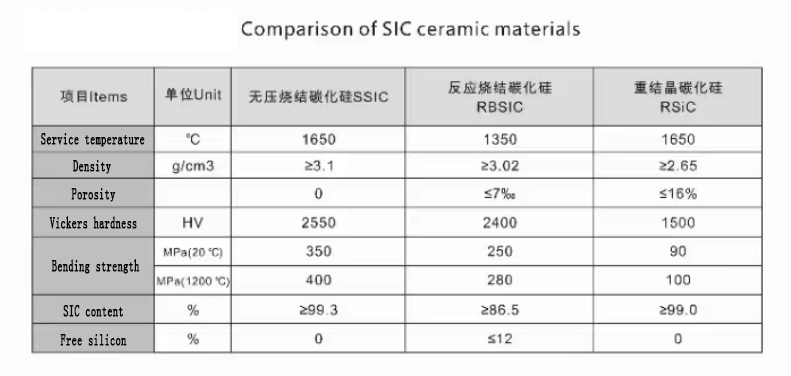

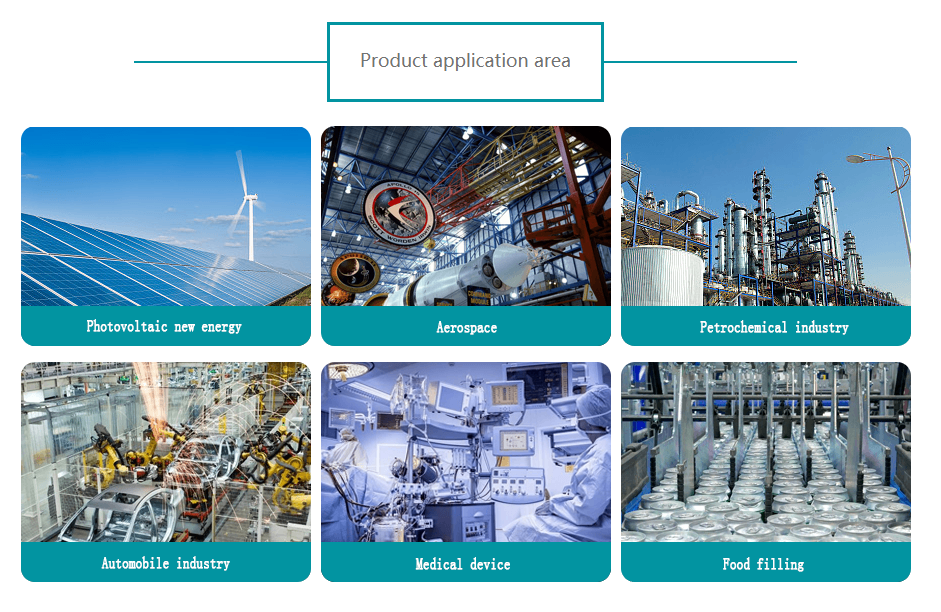

Silicon carbide ceramic materials have high temperature strength, good wear resistance, good thermal stability, small thermal expansion coefficient, high thermal conductivity, high hardness, thermal shock resistance and chemical corrosion resistance and other excellent characteristics, in the automotive, mechanical chemical industry, environmental protection, space technology, information electronics, energy and other fields have been increasingly widely used. It has become an irreplaceable structural ceramic with excellent performance of other materials in many industrial fields.

The advantages of silicon carbide plate:

1, silicon carbide plate resistant to 1900℃ high temperature,

2, silicon carbide plate resistance to hydrofluoric acid, sulfuric acid resistance,

3, the strength of silicon carbide plate is higher than quartz,

4, silicon carbide plate thermal conductivity 140W;

5, the bending strength of silicon carbide plate 380Mpa;

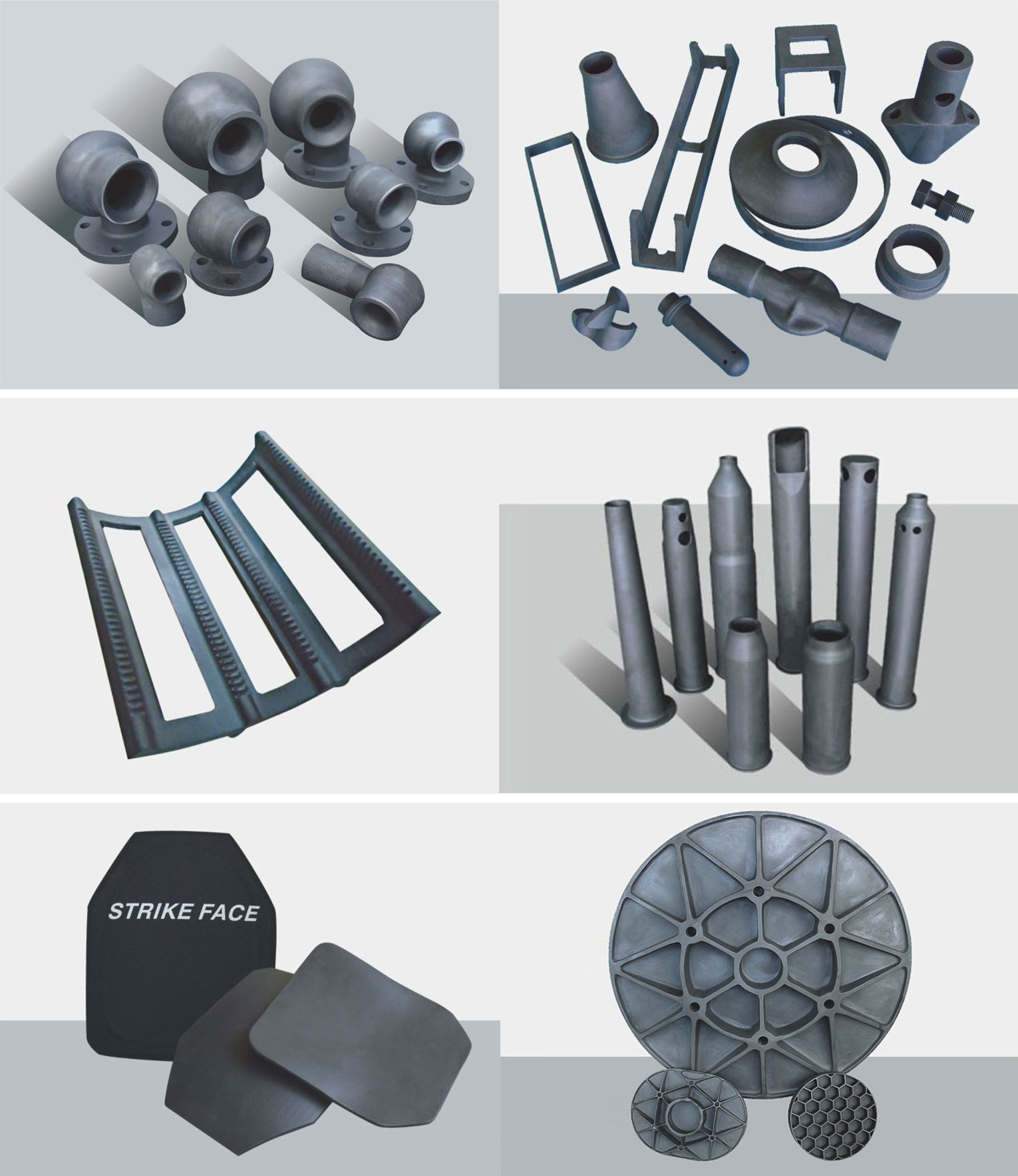

Semicera Energy Technology Co., Ltd is a professional research, development, production and sales of silicon carbide ceramic products. Since its establishment in 2016, Semicera Energy has mastered isostatic pressing molding process, thousand pressing molding process,grouting molding process and vacuum extrusion molding process. Our company uses 6 siliconcarbide ceramic sintering production lines, has 8 CNC, 6 precision grinding machines, can alsoprovide you with silicon carbide ceramic sintered products, but also can provide silicon carbideceramics, alumina ceramics, aluminum nitride ceramics, zirconia ceramics processing services.

-

Custom high quality silicon carbide grinding drum

-

Hot-selling Carbon Roller Rigid Felts Material ...

-

Hot New Products Kiln Furniture Sisic, Rbsic Re...

-

Hot sale Silicon Carbide Wear Resistant Parts S...

-

Excellent quality Material Roller Felts Carbon ...

-

Wholesale OEM Withstand 1700 º C/3092º F Silico...