Material property

Low density (3.10 to 3.20 g/cm3)

High hardness (HV10≥22 GPA)

High Young's modulus (380 to 430 MPa)

Corrosion and wear resistance even at high temperatures

Toxicological safety

Service capability

Extensive experience in the sintering, processing and polishing of precision ceramics enables us to:

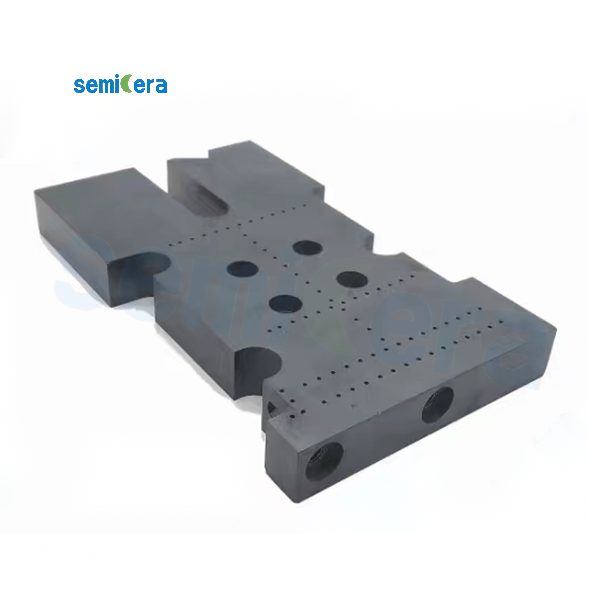

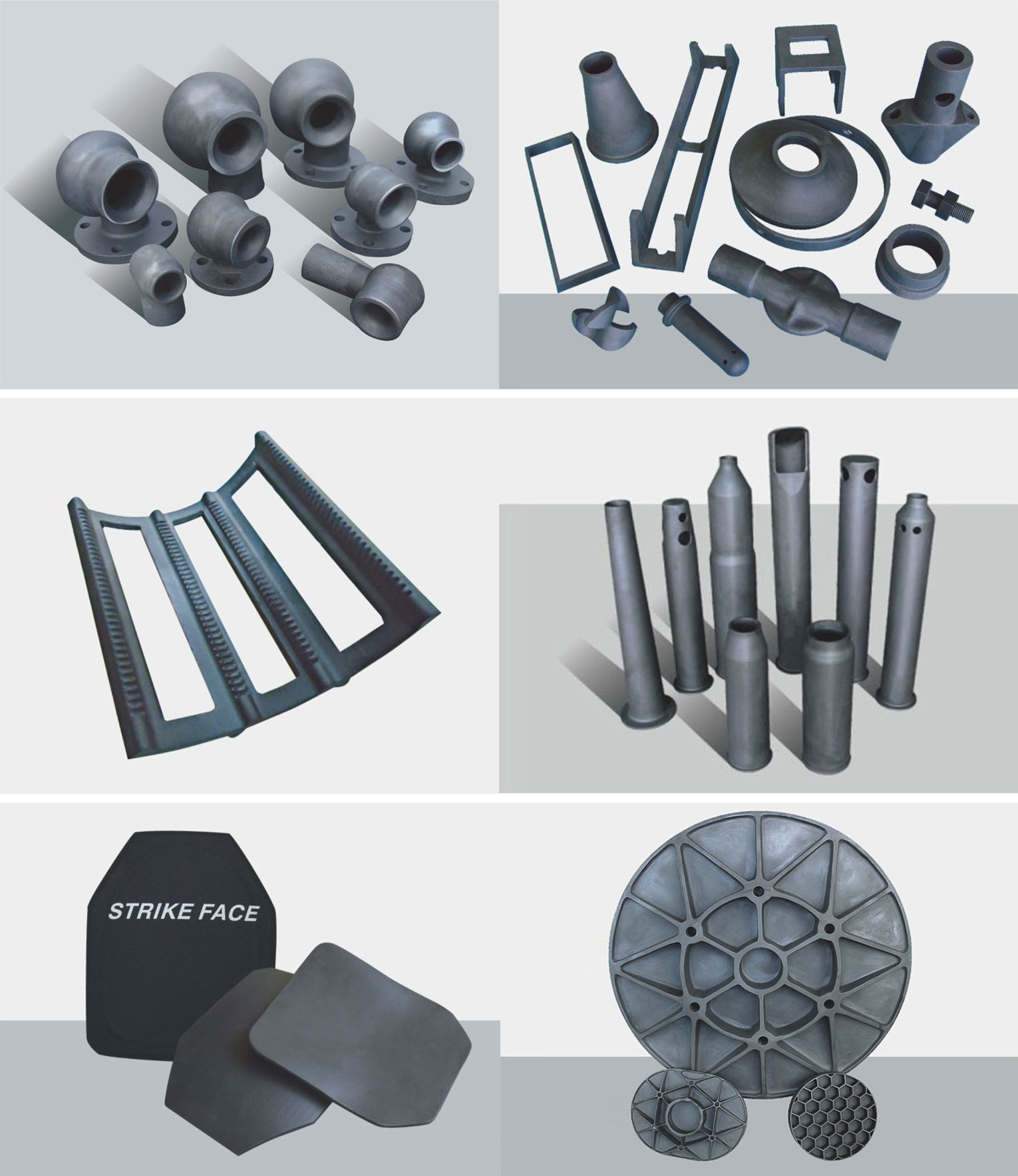

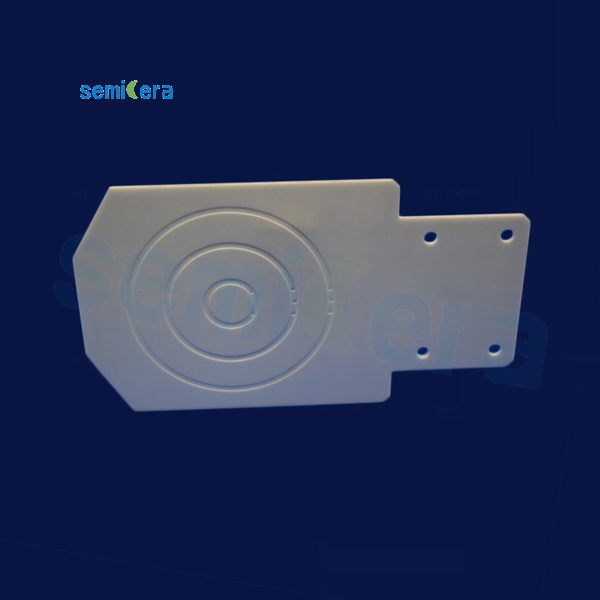

► The structure and size of silicon carbide structural parts can be customized according to demand;

► Shape accuracy can best reach ±0.005mm, under normal circumstances ±0.05mm;

► Internal structure accuracy can preferably reach ±0.01mm, under normal circumstances within ±0.05mm;

► Can process M2.5 or more standard or non-standard threads according to demand;

► Hole position accuracy can best reach 0.005mm, generally within 0.01mm;

► For additional details of the structure, please contact us.

All tolerances can be modified according to the size, structure and geometry of precision ceramic structural parts, ensuring that we only deliver products that meet or exceed our customers' highest quality requirements.

-

China wholesale Factory Price Custom Industrial...

-

Cheapest Factory High Quality Graphite Rigid Fe...

-

Top Suppliers High Temperature Silicon Carbide ...

-

Good quality H Type Silicon Carbide Sic Rod Hea...

-

Hot Sale for High Thermal Conductivity Silicon ...

-

OEM Manufacturer Heat Resistance / Roller Therm...