What is high-purity quartz?

High-purity quartz is a high-tech strategic mineral resource that is scarce both globally and in short supply in China. It is an irreplaceable mineral raw material for manufacturing high-tech quartz glass and a rare common high-value-added mineral resource demanded by strategic emerging industries.

High-purity quartz is a natural mineral with an aluminum lattice impurity content (lattice AI) of no more than 30 micrograms per gram (×10-6) formed by the finite allotropy substitution of aluminum and silicon in the quartz crystal lattice.

The main application fields of high-purity quartz products

At present, the development of the new generation of information and communication science and technology (ICT) represented by cloud computing, big data, intelligent manufacturing and 5G has accelerated the birth of a new round of technological revolution and industrial transformation. Developing strategic emerging industries is the key to solving the problems of China’s industrial development today. High-purity quartz is closely related to eight out of the nine major fields in strategic emerging industries, including new-generation information technology and new materials industry, and is an important supporting material in strategic emerging industries.

The semiconductor, optical communication, photovoltaic, optical, and electric light source industries and fields are important areas that support the development of strategic emerging industries. They are crucial guarantees for building major projects, improving people’s livelihoods, and consolidating national defense and military industries. They hold a significant position in the national economic construction. High-purity quartz is widely used in these industries and fields. It is the scarce common high-value-added mineral resources demanded by these fields.

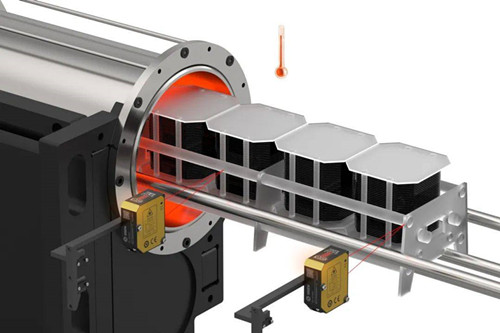

Optical fiber communication

Optical fiber is a tool for optical transmission and is widely used in the optical fiber communication industry. Optical fiber communication has high anti-interference performance, high speed and large transmission capacity, and has become an important pillar of modern communication. Plastic optical fibers and quartz optical fibers are the two main types of optical fibers. Compared with plastic optical fibers, quartz optical fibers have developed earlier and have mature technology. Their excellent performance characteristics are widely used.

The semiconductor industry

The semiconductor industry is known as the pearl of a country’s industry, reflecting a nation’s comprehensive strength. Semiconductor components are widely used in fields such as communication, 3C, and computers. The processing of wafers in the ultra-clean workshop and quartz crucibles are applications of high-purity quartz products in the semiconductor industry. The semiconductor industry requires the use of quartz sand with very high purity.

Photovoltaic industry

Quartz is one of the key raw materials in the photovoltaic industry. Its main application forms include quartz crucibles, quartz tubes and various quartz equipment. Both monocrystalline silicon and polycrystalline silicon in the photovoltaic industry are high-purity substances, which requires that the quartz materials used in conjunction with them must be of high purity. Generally, the silica content of quartz sand used in photovoltaic applications should be greater than or equal to 99.99%, and the total content of impurity elements should be less than or equal to 25 μ g/g.

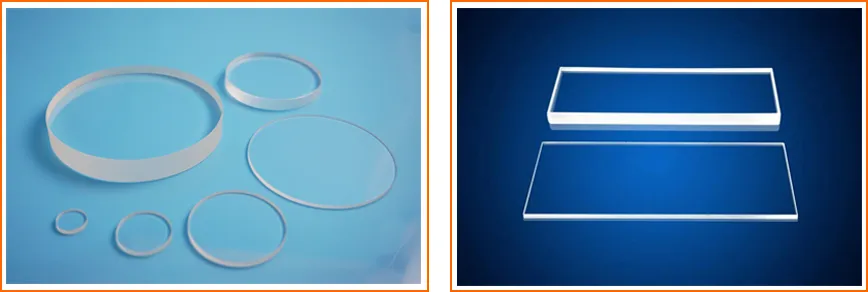

Optical industry

Optical glass features stable optical properties and high optical uniformity. It is widely used in the fields of light transmission, light storage and photoelectric display, and can be used as a glass material for manufacturing lenses, prisms, mirrors, Windows and other components of microscopic optical instruments or mechanical systems. High-purity quartz sand plays a crucial role as the main raw material in glass composites, accounting for 60% to 80% of the total. The quality of glass composites not only affects the quality of optical glass products but also influences the service life of glass melting furnaces. The usage environment of optical glass products has very high requirements for impurity content, refractive index, light transmittance, and microscopic defects. All these factors impose very strict quality requirements on the main raw material, quartz sand.

Post time: Sep-05-2025