-

How do tantalum carbide coated products enhance the corrosion resistance of materials?

Tantalum carbide coating is a commonly used surface treatment technology that can significantly improve the corrosion resistance of materials. Tantalum carbide coating can be attached to the surface of the substrate through different preparation methods, such as chemical vapor deposition, physica...Read more -

Yesterday, the Science and Technology Innovation Board issued an announcement that Huazhuo Precision Technology terminated its IPO!

Just announced the delivery of the first 8-inch SIC laser annealing equipment in China, which is also Tsinghua’s technology; Why did they withdraw the materials themselves? Just a few words: First, the products are too diverse! At first glance, I don’t know what they do. At present, H...Read more -

CVD silicon carbide coating-2

CVD silicon carbide coating 1. Why is there a silicon carbide coating The epitaxial layer is a specific single crystal thin film grown on the basis of the wafer through the epitaxial process. The substrate wafer and the epitaxial thin film are collectively called epitaxial wafers. Among them, the...Read more -

Preparation process of SIC coating

At present, the preparation methods of SiC coating mainly include gel-sol method, embedding method, brush coating method, plasma spraying method, chemical vapor reaction method (CVR) and chemical vapor deposition method (CVD). Embedding method This method is a kind of high-temperature solid-phase...Read more -

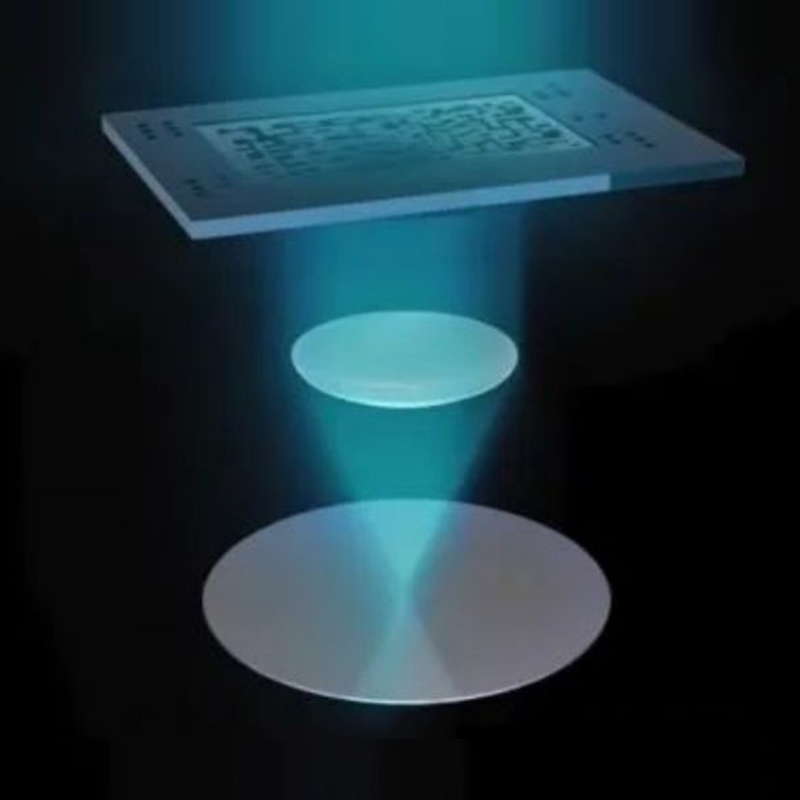

CVD Silicon Carbide Coating-1

What is CVD SiC Chemical vapor deposition (CVD) is a vacuum deposition process used to produce high-purity solid materials. This process is often used in the semiconductor manufacturing field to form thin films on the surface of wafers. In the process of preparing SiC by CVD, the substrate is exp...Read more -

Analysis of dislocation structure in SiC crystal by ray tracing simulation assisted by X-ray topological imaging

Research background Application importance of silicon carbide (SiC): As a wide bandgap semiconductor material, silicon carbide has attracted much attention due to its excellent electrical properties (such as larger bandgap, higher electron saturation velocity and thermal conductivity). These prop...Read more -

Seed crystal preparation process in SiC single crystal growth 3

Growth VerificationThe silicon carbide (SiC) seed crystals were prepared following the outlined process and validated through SiC crystal growth. The growth platform used was a self-developed SiC induction growth furnace with a growth temperature of 2200℃, a growth pressure of 200 Pa, and a growt...Read more -

Seed Crystal Preparation Process in SiC Single Crystal Growth (Part 2)

2. Experimental Process 2.1 Curing of Adhesive FilmIt was observed that directly creating a carbon film or bonding with graphite paper on SiC wafers coated with adhesive led to several issues: 1. Under vacuum conditions, the adhesive film on SiC wafers developed a scalelike appearance due to sign...Read more -

Seed Crystal Preparation Process in SiC Single Crystal Growth

Silicon carbide (SiC) material has the advantages of a wide bandgap, high thermal conductivity, high critical breakdown field strength, and high saturated electron drift velocity, making it highly promising in the semiconductor manufacturing field. SiC single crystals are generally produced throu...Read more -

What are the methods for wafer polishing?

Of all the processes involved in creating a chip, the final fate of the wafer is to be cut into individual dies and packaged in small, enclosed boxes with only a few pins exposed. The chip will be evaluated based on its threshold, resistance, current, and voltage values, but no one will consider ...Read more -

The Basic Introduction of SiC Epitaxial Growth Process

Epitaxial layer is a specific single crystal film grown on the wafer by ep·itaxial process, and the substrate wafer and epitaxial film are called epitaxial wafer. By growing the silicon carbide epitaxial layer on the conductive silicon carbide substrate, the silicon carbide homogeneous epitaxial...Read more -

Key points of semiconductor packaging process quality control

Key Points for Quality Control in Semiconductor Packaging ProcessCurrently, the process technology for semiconductor packaging has significantly improved and optimized. However, from an overall perspective, the processes and methods for semiconductor packaging have not yet reached the most perfec...Read more