Tantalum carbide (TaC) is a super-high temperature resistant ceramic material with the advantages of high melting point, high hardness, good chemical stability, strong electrical and thermal conductivity, etc. Therefore, TaC coating can be used as ablation-resistant coating, oxidation-resistant coating, and wear-resistant coating, and is widely used in aerospace thermal protection, third-generation semiconductor single crystal growth, energy electronics and other fields.

Process:

Tantalum carbide (TaC) is a kind of ultra-high temperature resistant ceramic material with the advantages of high melting point, high hardness, good chemical stability, strong electrical and thermal conductivity. Therefore, TaC coating can be used as ablation-resistant coating, oxidation-resistant coating, and wear-resistant coating, and is widely used in aerospace thermal protection, third-generation semiconductor single crystal growth, energy electronics and other fields.

Intrinsic characterization of coatings:

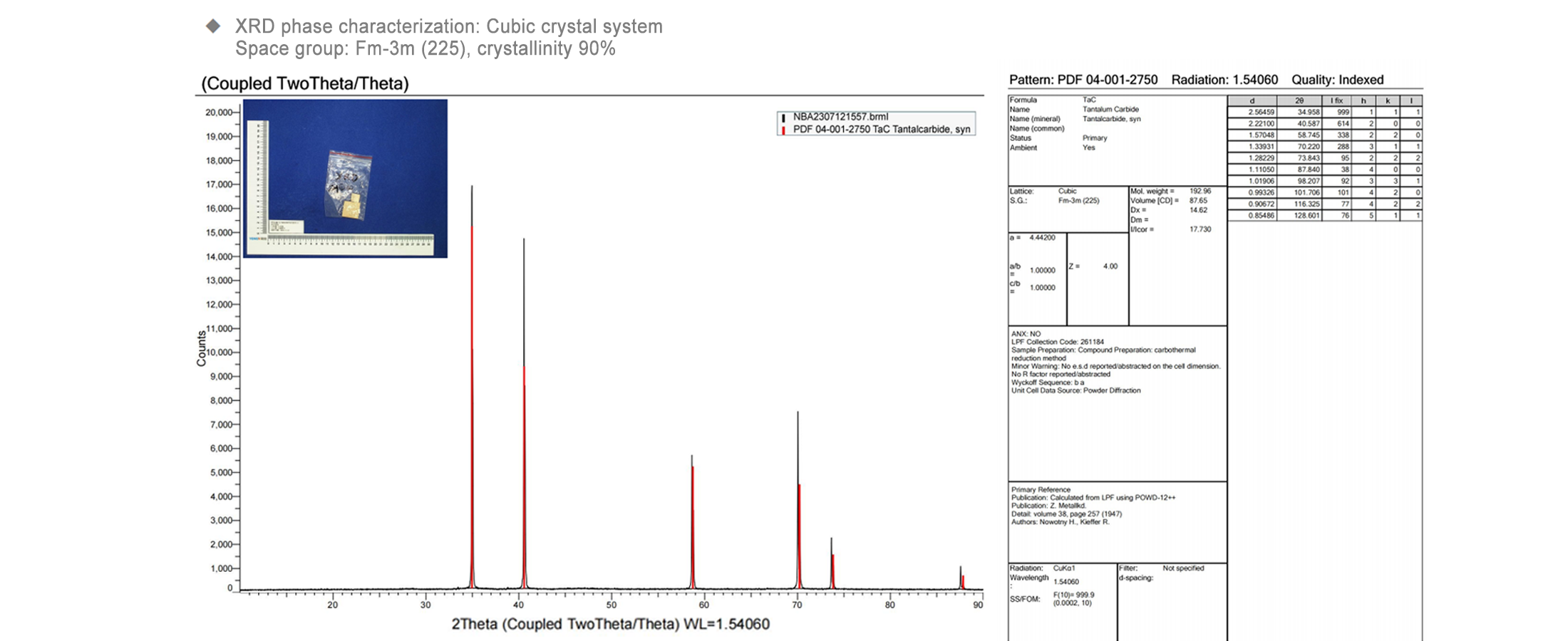

We use the slurry-sintering method to prepare TaC coatings of different thicknesses on graphite substrates of various sizes. First, high-purity powder containing Ta source and C source is configured with dispersant and binder to form a uniform and stable precursor slurry. At the same time, according to the size of graphite parts and the thickness requirements of TaC coating, the pre-coating is prepared by spraying, pouring, infiltration and other forms. Finally, it is heated to above 2200℃ in a vacuum environment to prepare a uniform, dense, single-phase, and well-crystalline TaC coating.

Intrinsic characterization of coatings:

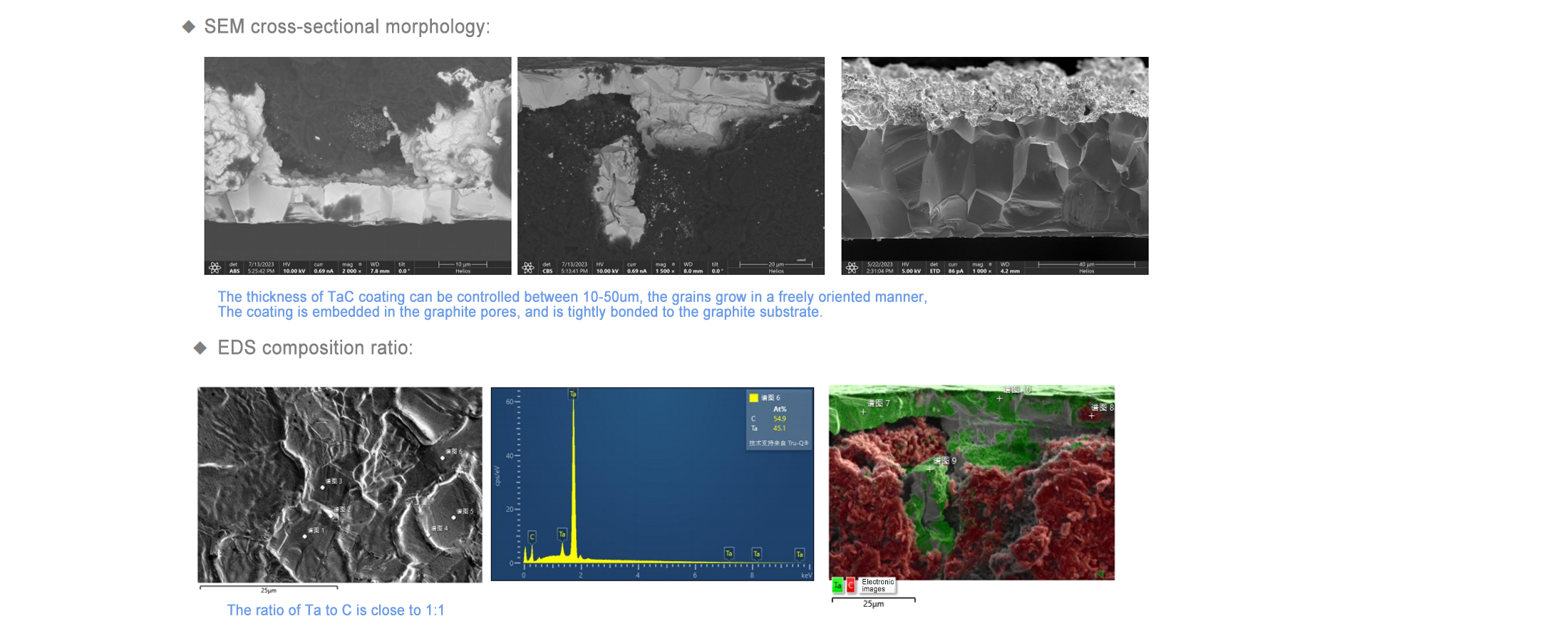

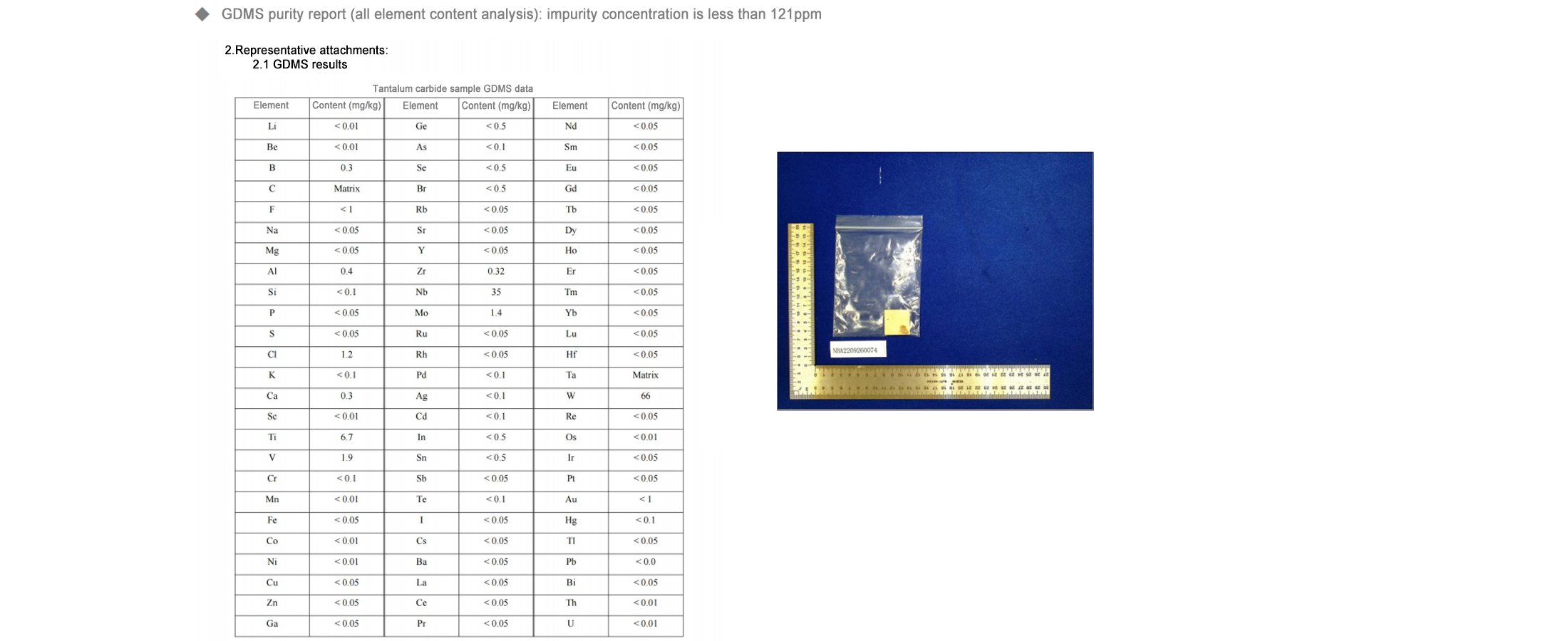

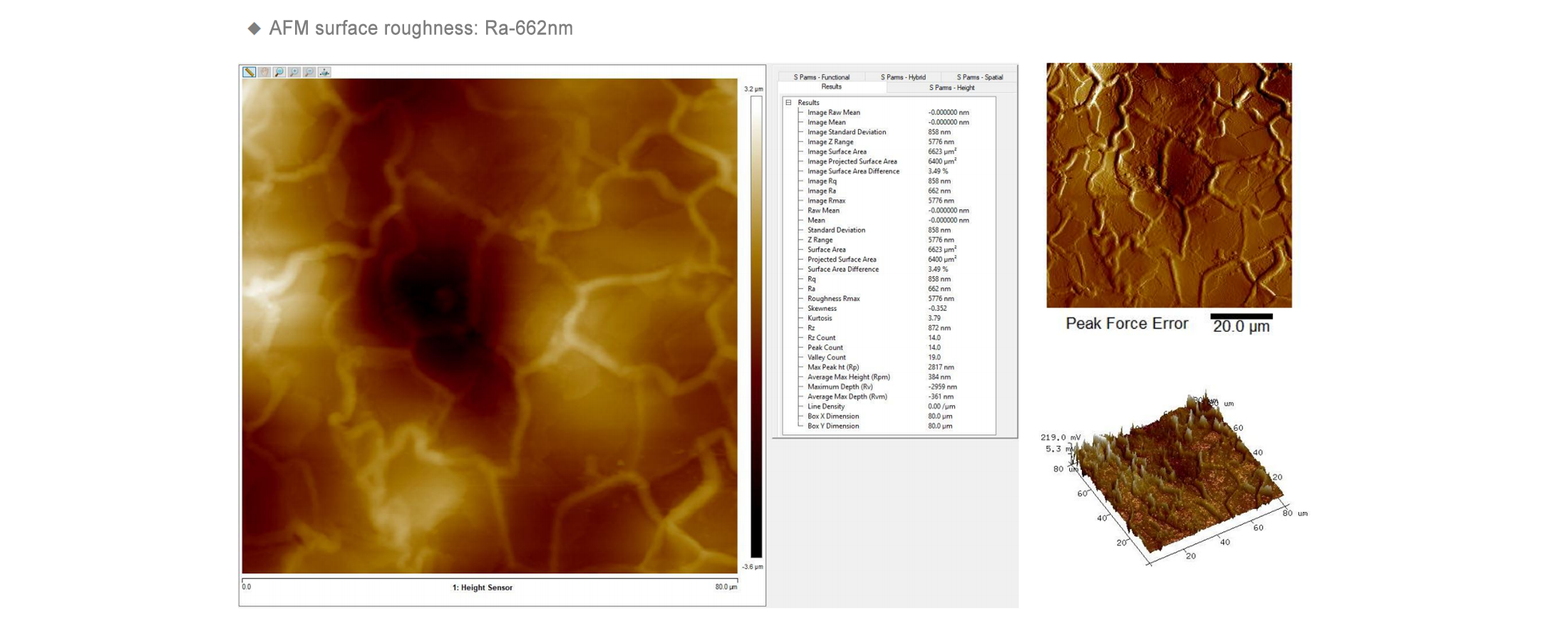

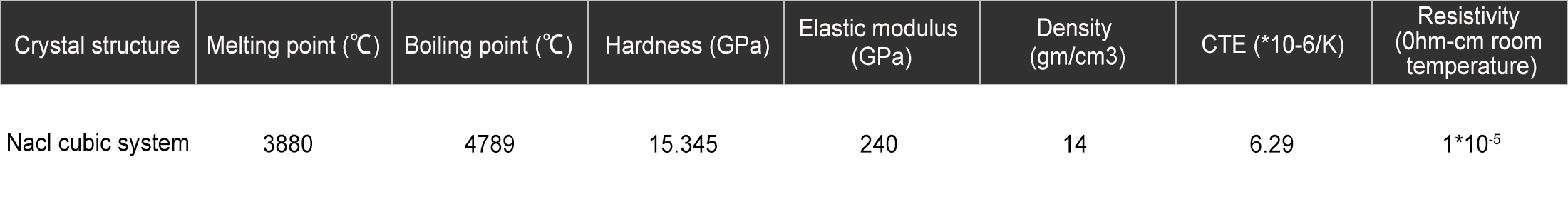

The thickness of TaC coating is about 10-50 μm, the grains grow in a free orientation, and it is composed of TaC with a single-phase face-centered cubic structure, without other impurities; the coating is dense, the structure is complete, and the crystallinity is high. TaC coating can fill the pores on the surface of graphite, and it is chemically bonded to the graphite matrix with high bonding strength. The ratio of Ta to C in the coating is close to 1:1. The GDMS purity detection reference standard ASTM F1593, the impurity concentration is less than 121ppm. The arithmetic mean deviation (Ra) of the coating profile is 662nm.

General Applications:

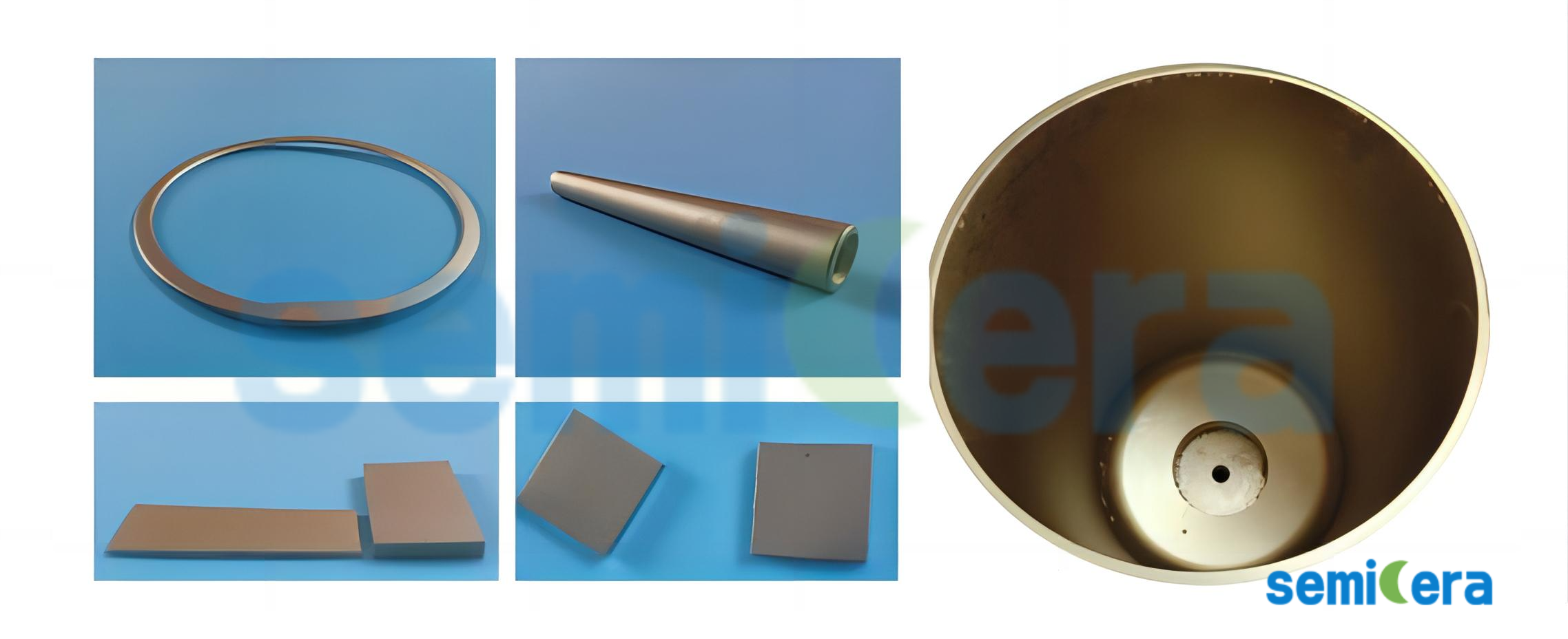

GaN and SiC epitaxial CVD reactor components, including wafer carriers, satellite dishes, showerheads, top covers and susceptors.

SiC, GaN and AlN crystal growth components, including crucibles, seed crystal holders, flow guides and filters.

Industrial components, including resistive heating elements, nozzles, shielding rings and brazing fixtures.

Key features:

High temperature stability at 2600℃

Provides steady-state protection in harsh chemical environments of H2, NH3, SiH4 and Si vapor

Suitable for mass production with short production cycles.