Different concept

Alumina ceramic is a kind of ceramic material with alumina (AI203) as the main body.

Transparent ceramics are obtained by using high purity ultra-fine ceramic raw materials and eliminating pores by technological means.

Composition and classification are different

Alumina ceramics are divided into high purity type and ordinary type two.

High-purity alumina ceramics are ceramic materials with AI203 content above 99.9%.Due to its sintering temperature as high as 1650-1990℃ and transmission wavelength of 1~6um, it is generally made into molten glass to take a generation of platinum crucible; Use its light transmission and alkali metal corrosion resistance as sodium lamp tube; It can be used as integrated circuit board and high frequency insulation material in the electronics industry.

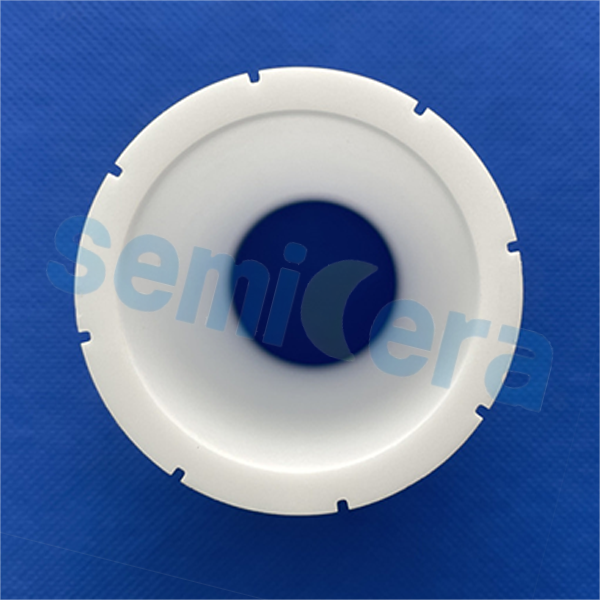

Ordinary alumina ceramics are divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain and other varieties according to the content of A1203, and sometimes the A1203 content is also classified as ordinary alumina ceramics series. The 99 alumina ceramic material is used to make high temperature crucible, refractory furnace pipe and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valves; 95 alumina porcelain is mainly used as corrosion resistance and wear resistance parts; The 85 porcelain is often mixed with talc to improve the electrical properties and mechanical strength, and can be sealed with molybdenum, niobium, tantalum and other metals, and some are used as electric vacuum devices.

Transparent ceramics can be divided into aluminum oxide transparent ceramics, yttrium oxide transparent ceramics, magnesium oxide transparent ceramics, yttrium aluminum garnet transparent ceramics, aluminum magnesium acid transparent ceramics, transparent ferroelectric ceramics, aluminum nitride transparent ceramics, aluminum nitride transparent ceramics, magnesium aluminum spinel transparent ceramics and so on.

Different performance

Alumina ceramic properties:

1. High hardness determined by the Shanghai Institute of Silicate of the Chinese Academy of Sciences, its Rockwell hardness is HRA80-90, the hardness is second only to diamond, far exceeding the wear resistance of wear-resistant steel and stainless steel.

2. Excellent wear resistance Measured by the Powder Metallurgy Institute of Central South University, its wear resistance is equivalent to 266 times of manganese steel and 171.5 times of high chromium cast iron. According to our customer tracking survey for more than ten years, under the same working conditions, the service life of the equipment can be extended at least ten times.

3. Light weight Its density is 3.5g/cm3, which is only half of steel, which can greatly reduce the load of equipment.

Transparent ceramic properties:

Transparent ceramics as a branch of advanced ceramics, in addition to inheriting ceramic high temperature resistance, corrosion resistance, high strength, high hardness, chemical stability, low expansion coefficient in addition, the unique light transmission makes it increase many applications.

Different application

Alumina ceramics are widely used in machinery, optical fiber, cutting tools, medical, food, chemical, aerospace and other industries.

Transparent ceramics are mainly used in lighting fixtures, laser materials, infrared window materials, flicker ceramics, electro-optical ceramics, bulletproof materials.

Post time: Sep-18-2023