In the world of semiconductor manufacturing, precision and material integrity are key. Among the many components that contribute to the efficiency and reliability of the production process, quartz wafer boats stand out. These seemingly simple but crucial tools are used extensively in the deposition, etching, and annealing processes that are fundamental in the production of semiconductors. This article will delve into what quartz wafer boats are, their significance in the semiconductor industry, and how they contribute to the manufacturing of high-performance integrated circuits (ICs).

What Is a Quartz Wafer Boat?

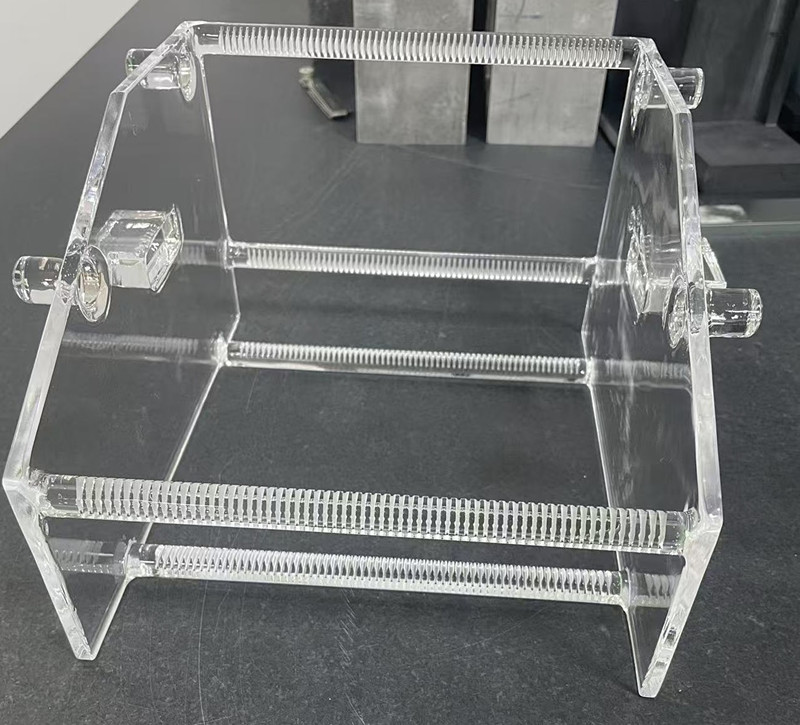

A quartz wafer boat is a specialized piece of equipment used to hold silicon wafers during various semiconductor manufacturing processes, such as chemical vapor deposition (CVD), plasma etching, and thermal processing. Typically, quartz wafer boats are designed with multiple slots where the wafers can be placed vertically or horizontally, depending on the process requirements. Quartz, with its exceptional resistance to thermal expansion, high-temperature stability, and inert nature, is the ideal material for fabricating these boats.

The primary purpose of the quartz wafer boat is to provide a stable and reliable holder for the wafers, ensuring that they are not subjected to contamination, mechanical stress, or any form of chemical interaction that could compromise the integrity of the wafer. Given the delicate and sensitive nature of semiconductor fabrication, even minor impurities or defects in wafer handling can lead to major issues in the final product.

Why Quartz? The Material of Choice

Quartz has several properties that make it the material of choice for wafer boats in semiconductor manufacturing:

1.Thermal Stability: Quartz has a high melting point (about 1,650°C) and excellent thermal shock resistance. This allows it to endure the high temperatures required in processes such as thermal oxidation or annealing without degrading or deforming.

2.Chemical Inertness: Quartz is chemically inert and does not react with most acids, bases, or solvents. This is crucial in semiconductor manufacturing, where even minute contamination from reactive materials can compromise the quality of the wafers.

3.Non-Conductive: Quartz is an electrical insulator, which helps in preventing unintended electrical interactions during processing, reducing the likelihood of electrical damage to the wafers.

4.Low Thermal Expansion: The low thermal expansion coefficient of quartz means that it expands and contracts very little when subjected to temperature changes. This ensures that the wafer boat maintains its shape and structural integrity during rapid heating and cooling cycles.

Applications of Quartz Wafer Boats in Semiconductor Manufacturing

Quartz wafer boats play a pivotal role in several critical processes involved in semiconductor manufacturing. Some of the key applications include:

1. Chemical Vapor Deposition (CVD)

In the CVD process, thin films of various materials, such as silicon dioxide or metal nitrides, are deposited onto semiconductor wafers. Quartz wafer boats are used to hold the wafers in the CVD reactor, where they are exposed to gaseous precursors at elevated temperatures. The high-temperature stability and chemical inertness of quartz ensure that the wafer boat does not interfere with the deposition process or introduce contamination.

2. Annealing and Oxidation

Annealing, which involves heating the wafer to a specific temperature and then cooling it at a controlled rate, is essential for activating dopants and relieving stress in the silicon wafer. Quartz wafer boats are commonly used in high-temperature furnaces during the annealing process, as they can withstand the extreme temperatures without affecting the wafer’s quality.

Similarly, during oxidation, where a layer of silicon dioxide is grown on the wafer surface by exposing it to oxygen at high temperatures, quartz wafer boats are used to hold the wafers in the furnace, ensuring uniform exposure to the oxidizing atmosphere.

3. Plasma Etching

In plasma etching, a plasma is used to etch away material from the wafer’s surface to form intricate patterns for circuits. Quartz wafer boats provide a stable environment for wafers in the etching chamber, preventing contamination from other materials or substances that could negatively affect the etching process.

The Importance of Proper Maintenance and Handling

Although quartz is a highly durable material, quartz wafer boats are not immune to wear and tear. Over time, repeated exposure to extreme temperatures and chemicals can cause subtle changes in the quartz structure, such as surface degradation, cracking, or contamination buildup. As such, regular inspection and maintenance are essential to ensure that quartz wafer boats continue to perform effectively.

1.Cleaning: Quartz wafer boats need to be cleaned thoroughly after each use to remove any contamination, dust, or chemical residues. Special cleaning procedures, such as using acid or solvent-based cleaning agents, are often employed to ensure the boats are pristine before reuse.

2.Inspection: Regular inspection for cracks or other defects is essential. A compromised wafer boat could result in wafer contamination, which in turn leads to a higher rate of defects in the final semiconductor products.

3.Replacement: Despite their robustness, quartz wafer boats eventually need to be replaced due to accumulated wear. Using a damaged boat can result in poor wafer processing, leading to production delays and cost inefficiencies.

Choosing the Right Quartz Wafer Boat for Your Needs

When selecting a quartz wafer boat, several factors should be taken into account to ensure optimal performance. These factors include the size and design of the boat, the number of slots for wafers, and the specific material properties required for the process being undertaken.

1.Size and Design: The size of the wafer boat should correspond to the size of the wafers being processed. Standard wafer sizes include 100mm, 150mm, 200mm, and 300mm, and wafer boats are manufactured to accommodate these sizes. Some boats are designed with more intricate slots or specialized coatings to meet the needs of specific processes.

2.Material Quality: Not all quartz materials are the same. High-quality fused quartz, which is free of bubbles and other impurities, is essential to ensuring the durability and reliability of the wafer boat. The purity of the quartz used can also influence the rate of contamination and the longevity of the wafer boat.

3.Coatings and Customization: For specialized processes, some wafer boats may be coated with additional layers of materials to improve their performance. For example, some boats may have a special coating to reduce particle contamination or to enhance their thermal properties.

As the demand for smaller, faster, and more efficient electronics continues to grow, the importance of maintaining and utilizing high-quality quartz wafer boats will only increase.

Post time: Sep-09-2025