-

Structure and growth technology of silicon carbide (Ⅰ)

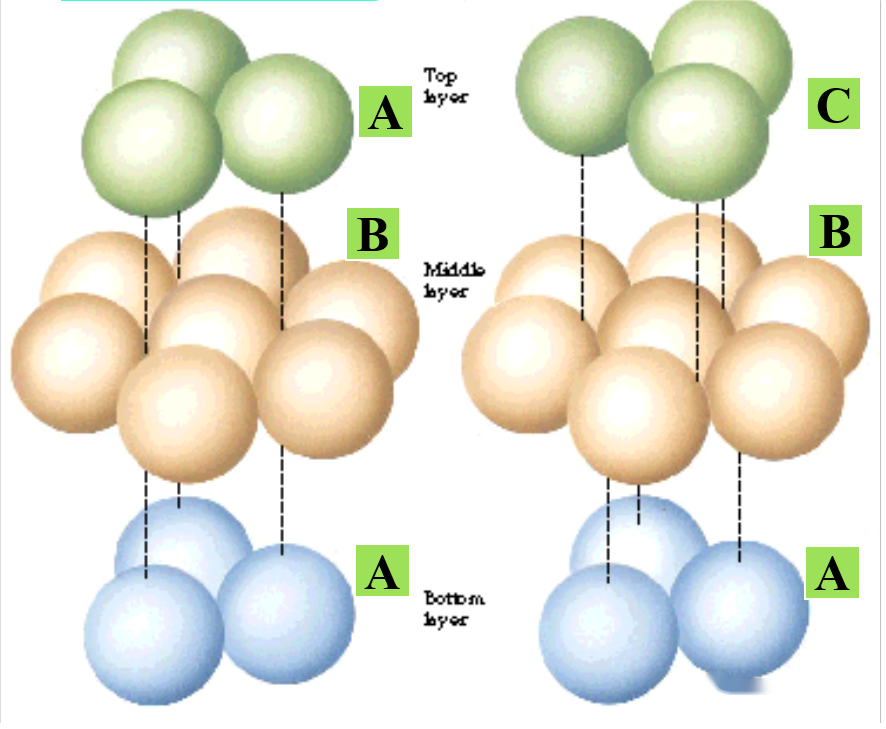

First, the structure and properties of SiC crystal. SiC is a binary compound formed by Si element and C element in 1:1 ratio, that is, 50% silicon (Si) and 50% carbon (C), and its basic structural unit is SI-C tetrahedron. Schematic diagram of silicon carbide tetrahedro...Read more -

Advantages of tantalum carbide coating in semiconductor products

With the continuous progress of science and technology, semiconductor products are playing an increasingly important role in our lives. In the semiconductor manufacturing process, the application of coating technology has become increasingly important. As a material wide...Read more -

Silicon carbide nozzles in electronic semiconductor manufacturing

Silicon carbide nozzles play an important role in electronic semiconductor manufacturing. They are a device used to spray liquids or gases, often used for wet chemical treatment in semiconductor manufacturing. Sic nozzle has the advantages of high temperature resistance,...Read more -

Excellent performance of silicon carbide crystal boat in high temperature environment

Silicon carbide crystal boat is a material with excellent properties, showing extraordinary heat and corrosion resistance in high temperature environments. It is a compound composed of carbon and silicon elements with high hardness, high melting point and excellent therm...Read more -

Explore The Unique Properties and Applications of Glass Carbon

Carbon is one of the most common elements in nature, encompassing the properties of nearly all substances found on Earth. It exhibits a wide range of characteristics, such as varying hardness and softness, insulation-semiconductor-superconductor behavior, heat insulation-superconductivity, and li...Read more -

Semicera Introduces Innovative Graphite Products, Providing Outstanding Solutions to the Industry

Semicera, a global leader in graphite product manufacturing, has recently announced the launch of a range of innovative products, delivering exceptional solutions to the industry. As a leading company in this field, Semicera is committed to providing high-quality and high-performance graphite pro...Read more -

What Are Power Semiconductors? Understanding the Rapid Growth of This Market!

As one of the leading companies in the industry, Semicera is dedicated to providing innovative solutions to our customers. In this article, we will explore the concept of power semiconductors and gain an understanding of why this market is experiencing rapid growth. Understanding Power Semiconduc...Read more -

Production technology and main uses of isostatic pressed graphite

Isostatic pressed graphite is a new type of graphite material, which has excellent electrical conductivity, high temperature resistance and chemical stability, so it is widely used in many high-tech fields. This paper will introduce in detail the production process, main...Read more -

Exploring semiconductor silicon carbide epitaxial disks: Performance advantages and application prospects

In today's field of electronic technology, semiconductor materials play a crucial role. Among them, silicon carbide (SiC) as a wide band gap semiconductor material, with its excellent performance advantages, such as high breakdown electric field, high saturation speed, h...Read more -

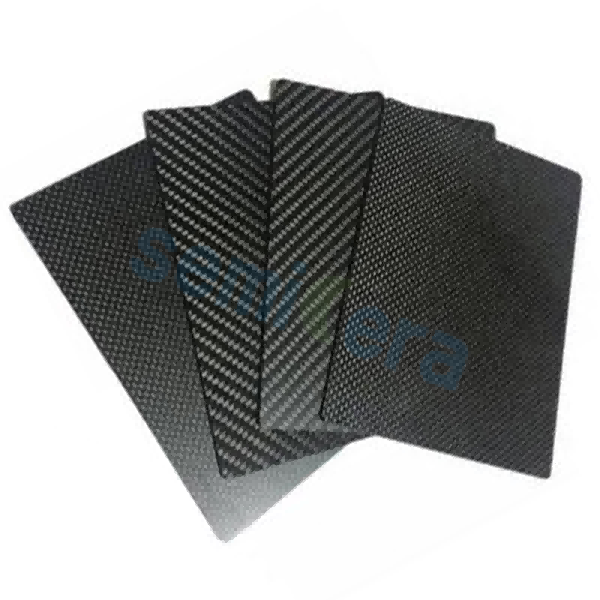

Graphite hard felt – innovative material, open a new era of science and technology

As a new material graphite hard felt, the manufacturing process is quite unique. During the mixing and felting process, graphene fibers and glass fibers interact to form a new material that retains both the high electrical conductivity and high strength of graphene and ...Read more -

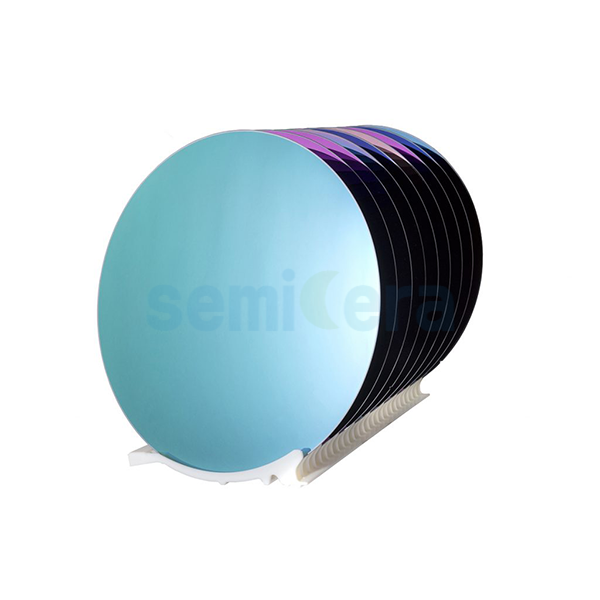

What is semiconductor silicon carbide (SiC) wafer

Semiconductor silicon carbide (SiC) wafers, this new material has gradually emerged in recent years, with its unique physical and chemical properties, injected a new vitality for the semiconductor industry. SiC wafers, using monocrystals as raw materials, are carefully g...Read more -

Silicon carbide wafer production process

Silicon carbide wafer is made of high purity silicon powder and high purity carbon powder as raw materials, and silicon carbide crystal is grown by physical vapor transfer method (PVT), and processed into silicon carbide wafer. 1.Raw material synthesis: High purity sili...Read more