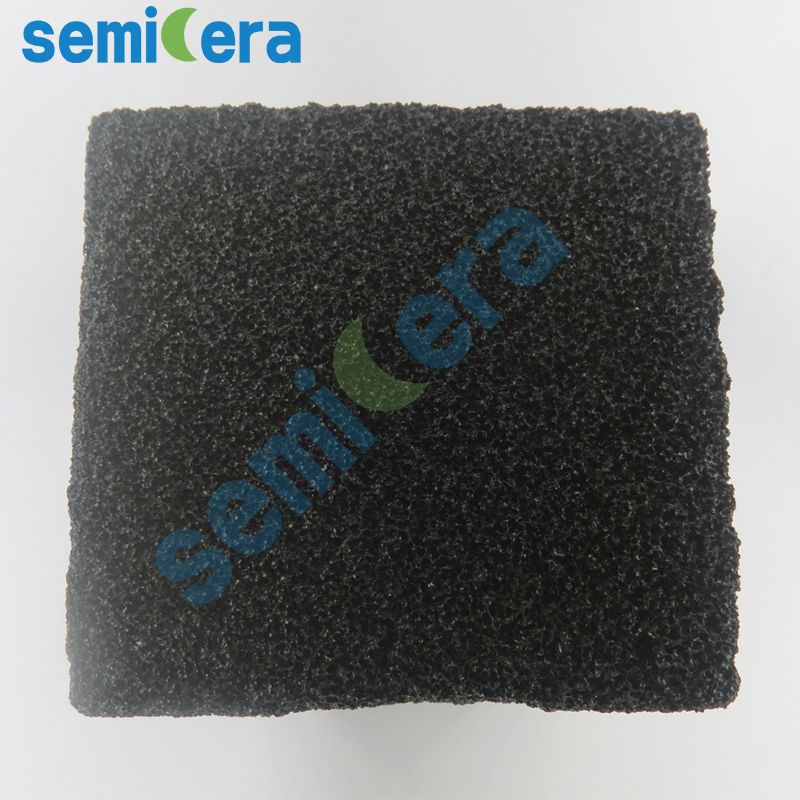

Porous Graphite: A Cutting-Edge Material with Exceptional Properties and Versatile Applications

Porous graphite is a material composed of graphene layers arranged into a three-dimensional network structure through specific fabrication processes. Unlike traditional graphite, its standout feature is the abundance of nano-sized pores within its structure, which form interconnected channels. This unique architecture endows the material with a remarkably high specific surface area, with some types exceeding 2000 m²/g.

Fabrication Methods for Porous Graphite

Among the various fabrication methods, chemical vapor deposition (CVD) is currently the most established technique. By precisely controlling parameters such as reaction temperature and gas flow, a graphite structure with a specific pore size distribution can grow on the surface of metal catalysts. Another more economical approach involves graphite oxidation-reduction. This method starts with graphite oxidation, followed by exfoliation into graphene oxide. The material is then dried using freeze-drying or supercritical drying techniques to form a three-dimensional framework, and finally reduced at high temperatures to yield porous graphite. This approach is simpler and more suitable for large-scale production.

Key Advantages of Porous Graphite

Porous graphite offers several key advantages that make it highly attractive for various applications:

-

Outstanding Electrical Conductivity: Its conductivity can reach over 1000 S/m, thanks to the integrity of the graphene sheets.

-

Excellent Thermal Stability: It can withstand temperatures as high as 2000°C in inert atmospheres.

-

Adjustable Pore Size Distribution: By optimizing the fabrication process, porous graphite can achieve a multi-level pore structure, ranging from micropores to macropores.

Applications of Porous Graphite

Porous graphite is making significant strides in several industries:

-

Energy Storage: In lithium-ion batteries, its porous structure helps reduce volume expansion during charge and discharge cycles, enhancing the cycle stability of the battery.

-

Environmental Protection: With its enormous surface area and diverse surface functional groups, porous graphite excels in adsorbing organic pollutants, making it ideal for wastewater treatment.

-

Biomedicine: Modified porous graphite can serve as a drug carrier, with its pore channels facilitating controlled drug release.

Challenges and Future Directions

Despite its promising potential, the industrialization of porous graphite faces some challenges, particularly in semiconductor applications. Additionally, further research is needed to fine-tune pore size control for specific application needs.

Semicera provides advanced porous graphite materials designed to enhance product yields and reduce production costs. Feel free to contact us for more information on how our products can support your needs.