LASER MICROJET (LMJ)

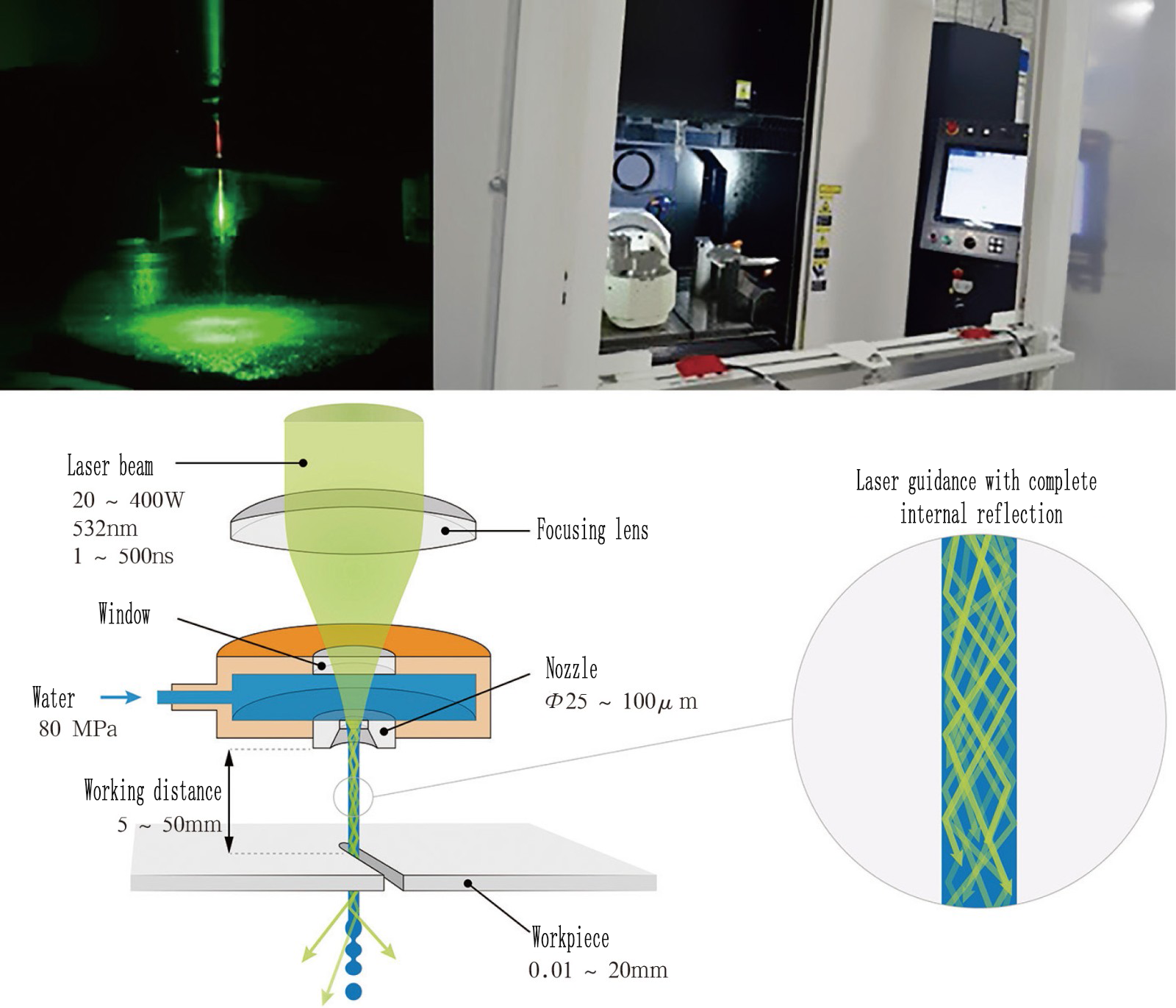

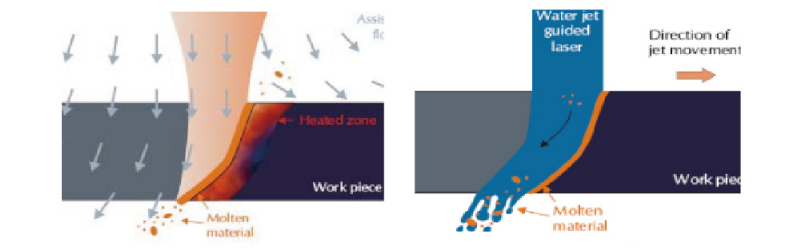

The focused laser beam is coupled into the high-speed water jet, and the energy beam with uniform distribution of cross section energy is formed after full reflection on the inner wall of the water column. It has the characteristics of low line width, high energy density, controllable direction and real-time reduction of surface temperature of processed materials, providing excellent conditions for integrated and efficient finishing of hard and brittle materials.

Laser micro-water jet machining technology takes advantage of the phenomenon of total reflection of laser at the interface of water and air, so that the laser is coupled inside the stable water jet, and the high energy density inside the water jet is used to achieve material removal.

ADVANTAGES OF LASER MICROJET

Microjet laser (LMJ) technology makes use of the propagation difference between water and air optical characteristics to overcome the inherent defects of conventional laser processing. In this technology, the laser pulse is fully reflected in the processed high-purity water jet in an undisturbed manner, as it is in an optical fiber.

From the perspective of use, the main features of LMJ microjet laser technology are:

1, the laser beam is a cylindrical (parallel) laser beam;

2, the laser pulse in the water jet like fiber conduction, the whole process is protected from any environmental factors;

3, the laser beam is focused inside the LMJ equipment, and there is no change in the height of the machined surface during the whole processing process, so that there is no need to continuously focus during the processing process with the change in the processing depth;

4, in addition to the ablation of the processed material at the moment of each laser pulse processing, about 99% of the time in the single time range from the beginning of each pulse to the next pulse processing, the processed material is in the real-time cooling of water, so as to almost eliminate the heat-affected zone and remelt layer, but maintain the high efficiency of processing;

5, continue to clean the surface.

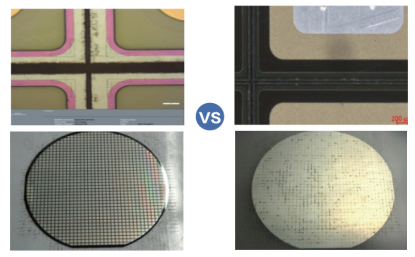

Device scribing

When traditional laser cutting, the accumulation and conduction of energy is the main cause of thermal damage on both sides of the cutting path, and the microjet laser, due to the role of the water column, will quickly take away the residual heat of each pulse will not accumulate on the workpiece, so the cutting path is clean. For the traditional "hidden cut" + "split" method, reduce the processing technology.