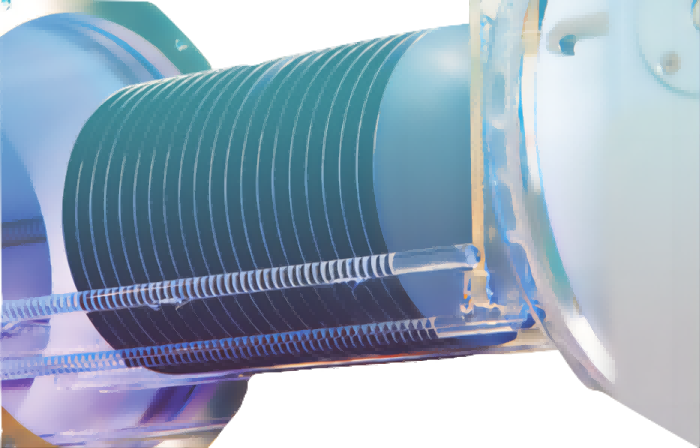

The thermal oxide layer of a silicon wafer is an oxide layer or silica layer formed on the bare surface of a silicon wafer under high temperature conditions with an oxidizing agent. The thermal oxide layer of silicon wafer is usually grown in a horizontal tube furnace, and the growth temperature range is generally 900 ° C ~1200 ° C, and there are two growth modes of "wet oxidation" and "dry oxidation". The thermal oxide layer is a "grown" oxide layer that has higher homogeneity and higher dielectric strength than the CVD deposited oxide layer. The thermal oxide layer is an excellent dielectric layer as an insulator. In many silicon-based devices, the thermal oxide layer plays an important role as a doping blocking layer and surface dielectric.

Tips: Oxidation type

1. Dry oxidation

The silicon reacts with oxygen, and the oxide layer moves toward the basal layer. Dry oxidation needs to be carried out at a temperature of 850 to 1200 ° C, and the growth rate is low, which can be used for MOS insulation gate growth. When a high quality, ultra-thin silicon oxide layer is required, dry oxidation is preferred over wet oxidation.

Dry oxidation capacity: 15nm~300nm(150A ~ 3000A)

2. Wet oxidation

This method uses a mixture of hydrogen and high-purity oxygen to burn at ~1000 ° C, thus producing water vapor to form an oxide layer. Although wet oxidation can not produce as high quality oxidation layer as dry oxidation, but enough to be used as an isolation zone, compared to dry oxidation has a clear advantage is that it has a higher growth rate.

Wet oxidation capacity: 50nm~ 15µm (500A ~15µm)

3. Dry method - wet method - dry method

In this method, pure dry oxygen is released into the oxidation furnace at the initial stage, hydrogen is added in the middle of the oxidation, and hydrogen is stored in the end to continue the oxidation with pure dry oxygen to form a denser oxidation structure than the common wet oxidation process in the form of water steam.

4. TEOS oxidation

|

Oxidation Technique |

Wet oxidation or Dry oxidation |

|

Diameter |

2″ / 3″ / 4″ / 6″ / 8″ / 12″ |

|

Oxide Thickness |

100 Å ~ 15µm |

|

Tolerance |

+/- 5% |

|

Surface |

Single Side Oxidation(SSO) / Double Sides Oxidation(DSO) |

|

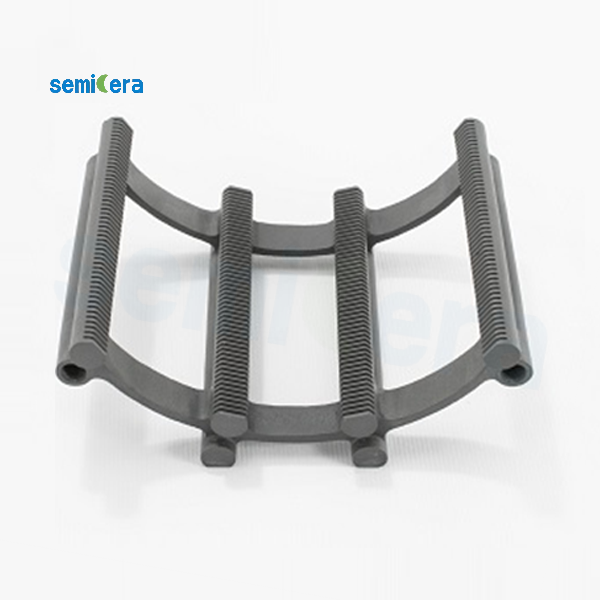

Furnace |

Horizontal tube furnace |

|

Gas |

Hydrogen and Oxygen gas |

|

Temperature |

900℃ ~ 1200 ℃ |

|

Refractive index |

1.456 |