Blue/green LED epitaxy from semicera offers cutting-edge solutions for high-performance LED manufacturing. Designed to support advanced epitaxial growth processes, semicera's Blue/green LED epitaxy technology enhances efficiency and precision in producing blue and green LEDs, critical for various optoelectronic applications. Utilizing state-of-the-art Si Epitaxy and SiC Epitaxy, this solution ensures excellent quality and durability.

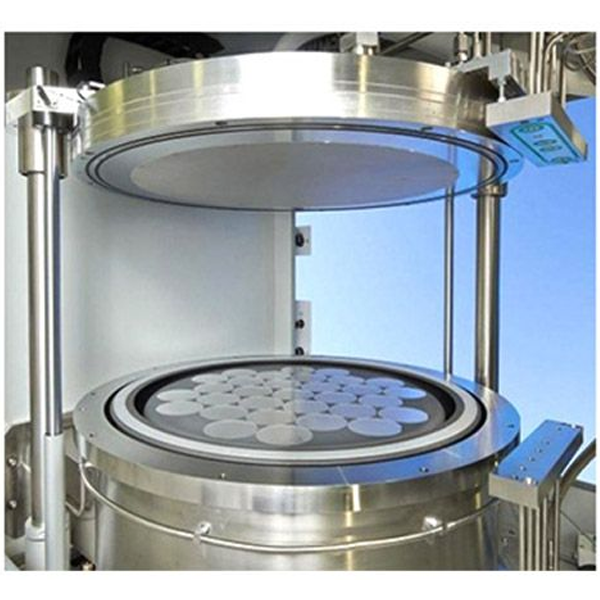

In the manufacturing process, MOCVD Susceptor plays a crucial role, along with components like PSS Etching Carrier, ICP Etching Carrier, and RTP Carrier, which optimize the epitaxial growth environment. Semicera's Blue/green LED epitaxy is designed to provide stable support for LED Epitaxial Susceptor, Barrel Susceptor, and Monocrystalline Silicon, ensuring the production of consistent, high-quality results.

This epitaxy process is vital for creating Photovoltaic Parts and supports applications such as GaN on SiC Epitaxy, improving overall semiconductor efficiency. Whether in a Pancake Susceptor configuration or used in other advanced setups, semicera's Blue/green LED epitaxy solutions offer reliable performance, helping manufacturers meet the growing demand for high-quality LED components.

Main features:

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity : made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coating

|

SiC-CVD Properties |

||

| Crystal Structure | FCC β phase | |

| Density | g/cm ³ | 3.21 |

| Hardness | Vickers hardness | 2500 |

| Grain Size | μm | 2~10 |

| Chemical Purity | % | 99.99995 |

| Heat Capacity | J·kg-1 ·K-1 | 640 |

| Sublimation Temperature | ℃ | 2700 |

| Felexural Strength | MPa (RT 4-point) | 415 |

| Young' s Modulus | Gpa (4pt bend, 1300℃) | 430 |

| Thermal Expansion (C.T.E) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |